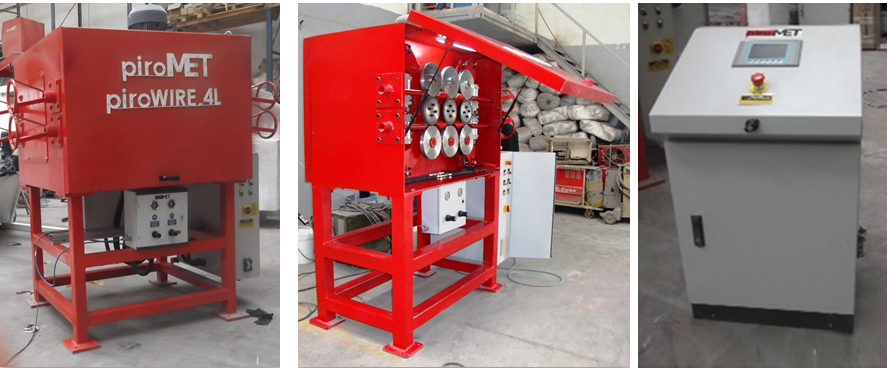

What is piroWIRE-Injector

The PiroWire-Injector is a state-of-the-art wire injection and feeding system, engineered specifically for secondary metallurgical processes. This advanced system delivers precise cored wire injection capabilities, enabling optimal alloy additions, deoxidation, and desulfurisation in steel production.

Key Features and Benefits

Multi-Strand Flexibility

- 2 to 4 strand capability - Scalable configuration to meet varying production demands

- Simultaneous multi-wire feeding for enhanced process efficiency

- Flexible strand management for different wire types and compositions

Advanced Injection Technology

- Cored wire injections/feeding optimised for secondary metallurgical processes.

- Precise wire feeding rates ensure accurate alloy additions and consistent results.

- Up to triple outlet configuration for comprehensive ladle treatment coverage

Intelligent Control System

- Full SCADA PC Control provides complete system automation and monitoring

- Real-time process data logging and analysis capabilities

- Remote operation and diagnostics for enhanced operational efficiency

- Integrated safety systems and process interlocks

Applications

Perfect for:

- Secondary Steel Refining - Ladle furnace operations

- Alloy Additions - Precise ferro-alloy and additive injection

- Deoxidation Processes - Aluminium and silicon wire feeding

- Desulfurisation - Calcium-based treatment applications

- Inclusion Modification - Shape control and cleanness improvement

Technical Advantages

- Precise Feed Rate Control - Ensures optimal metallurgical results.

- Multi-Wire Compatibility - Handles various cored wire types and diameters

- Robust Construction - Designed for harsh steelmaking environments

- Easy Integration - Compatible with existing ladle treatment systems

- Minimal Maintenance - Reliable operation with reduced downtime

Why Choose piroWIRE-Injector?

- Enhanced Steel Quality through precise alloy control

- Process Optimisation with real-time SCADA monitoring

- Operational Flexibility with scalable multi-strand design

- Proven reliability in demanding metallurgical applications

- Cost-Effective Solution for Secondary Refining Operations

Elevate your secondary metallurgical processes with piroWIRE-Injector - where precision meets performance for superior steel quality.

For detailed technical specifications, wire compatibility charts, and custom system configurations, contact the Vesuvius team.