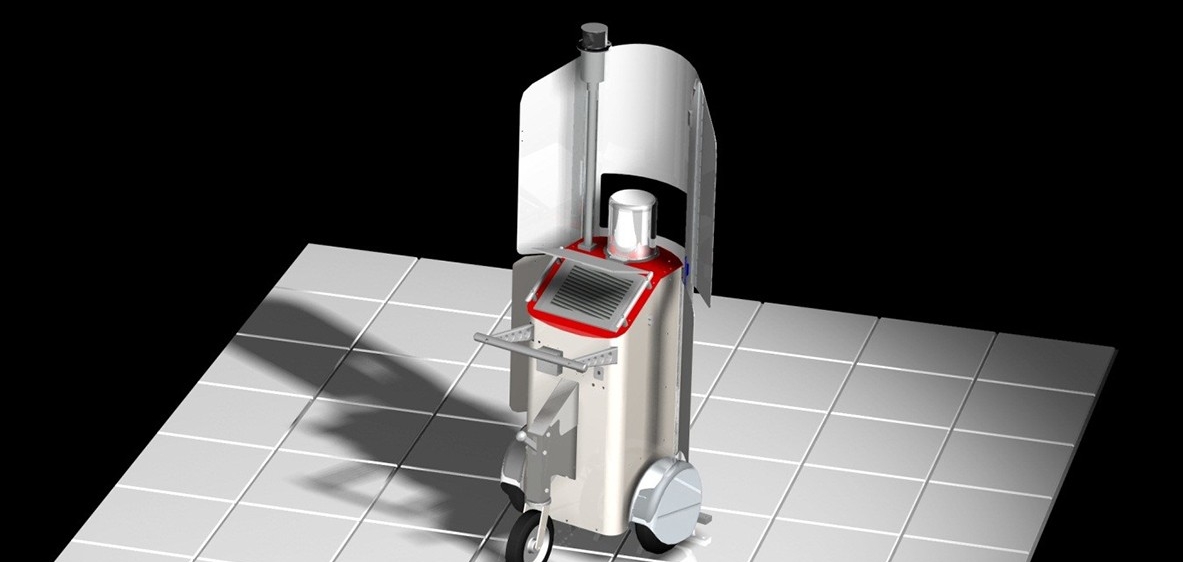

ANTERIS Mobile

Laser Contouring System (LCS)

Two principle objectives are emphasized in the PROCESS METRIX mobile platform design: SPEED and SIMPLICITY. Fast measurement times are achieved using our laser-based navigation system. Working from three reflectors mounted on the building structure behind the cart, this system automatically measures the cart position relative to the converter and reports position information directly to the LCS computer. The navigation system is completely automatic and updates 8 times per second. Also implemented is a radio frequency (RF) link that continuously broadcasts the vessel tilt to a receiver located in the cart. The RF-link incorporates 2.4 GHz spread-spectrum technology for interference-free transmission. During the measurement, the RF receiver automatically reports the vessel tilt to the LCS computer.

Together, the laser navigation system and RF link enable fast, error-free measurement of the vessel lining thickness. Measurements are initiated with a single tap to the fan less computer's 15" touch screen. Once the measurement process begins, the operator need only confirm the measured value of cart position and vessel tilt, the software does all the rest! Single measurements can be made in 20-30 seconds. An entire map of the vessel interior consisting of 4-6 measurements, and 500,000+ data points can be completed in less than 6-8 minutes.

ANTERIS Mobile Features

The ANTERIS Mobile also incorporates the following features:

- Intelligent data processing for smoke and dust filtering and enhanced accuracy

- Core duo 1.6 GHz industrial-grade fan less computer

- 3 USB, and one Ethernet (RJ-45) front panel port

- On-board battery power delivering up to three hours of continuous operation

- Continuous operation while battery charging (e.g. for printing, etc.)

- Internal, two-axis cart inclinometer

- WiFi for wireless interfacing to the mill's Level II system

- Pressure regulated Vortec cooler for extended operation in high temperature (+120° F/50° C) environments

- Retractable heat shielding

- Large diameter (16"/41 cm) wheels on spring suspension

The LCS software includes innovative data processing algorithms that maximize the information content of the thickness measurements. Our algorithms process everything in 3-D using detailed CAD representations of the vessel as a thickness reference. Measurements of the vessel shell and as-bricked profile can also be incorporated into the measurement sequence to more accurately represent the refractory profile.

More importantly, the 3-D processing capability facilitates intelligent dust and smoke filtering from the data set.

ANTERIS Mobile Specifications

| System Weight | 147 kg (325 lbs) |

Dimensions: Width (shields retracted) : Width (shields extended) : Height (shields retracted) : Height (shields extended) : Depth (approx) |

80cm (31.5") 99.5cm (39.2") 224cm (88.3") 224cm (88.3") 101.5cm (40.1") |

| Cooling System | Active cooling is not required for normal operation of the LCS system. However, certain conditions of high ambient temperature may require gas cooling of the range finding instrument. An integrated Vortex cooler creates a stream of super cooled gas from standard compressed air or nitrogen flow. A filter and regulator inside the cart removes moisture, oil and particulate matter from the gas stream before it enters the Vortex cooler. |

| Temperature/heat load tolerance: | Maximum surface temperature 1700°C (3092 °F). System withstands heat load immediately after tapping. |

| Connectivity- The cart rear panel supports the following interface(s): | USB (three) Ethernet (one) |

Software

Functional, Efficient Software Tools

The LCS software has two primary functions: Data acquisition and lining thickness calculation and display. The software also includes all of the setup functions that are used to configure our instrument in your application. Setup functions are password restricted, and most of our users don't access the configuration tools under normal, day-to day operation. All controls are highly intuitive, with label definitions implemented pictorially.

Our innovative completion grid tells the operator what sections of the vessel have and have not been measured. New vessel profiles are displayed automatically within five seconds after acquisition. Bath height, based on input values of charge weight and density, is also displayed on each view.

A high degree of output customization is available to tailor the view definitions to the needs and preferences of the operator. Two-dimensional slices through the vessel can be made at virtually any location (e.g. tap hole, trunion, or slag line). The vessel profile used to determine lining thickness is also displayed for visual reference. Contour maps of both the vessel wall and bottom clearly illustrate lining thickness over the entire vessel interior. Thickness values are displayed both numerically and by color key, immediately revealing regions that might require attention. The report generator automatically prints all views and screens needed by the mill to make informed process decisions. The report generator automatically prints all views and screens needed by the mill to make informed process decisions. The report generator automatically prints all views and screens needed by the mill to make informed process decisions. The report generator automatically prints all views and screens needed by the mill to make informed process decisions.