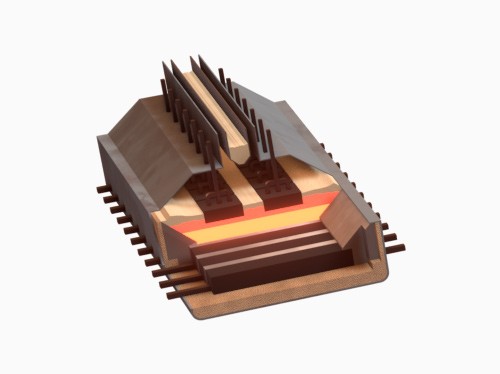

COMCAST slabs

Electrolytic pots rest on foundation, called sub-cathodic or barrier layer, typically made of hundreds of manually-laid bricks which could cost precious production time, especially if pots have to be relined ‘on-line’.

Vesuvius’ COMCAST sub-cathodic layer solution, proven by decades of use in several Australian smelters, replace hundreds of bricks with several precast, preassembled slabs, fitting together with tight tolerances and providing perfect horizontal plane.

COMCAST slabs offer several benefits for primary smelters:

Shorter pot turn-around time, which could add up to a couple of days of extra production time for the potline and thus tangible net savings

Labor savings, of over 40 man-hours per one pot, which is especially relevant for high labor cost countries and places with poor availability of highly skilled labor force

Improved EHS aspects, replacing manual masonry with machine installation

Less joints and more consistent installed properties of barrier layer refractories, resulting in safer pot operation / lower risk of molten metal leakages

SiC mortars

Silicon Carbide mortars are typically used during installation and repair works at electrolytic pots to fill the joints between the refractory tiles and ensure overall integrity of the vessel during operation. Choice of a particular SiC material depends on particular circumstances, including pot design, time of pot in operation, thickness and depth of the joints to be filled, typical ambient temperature, preferences of the operators, etc. That is why Vesuvius offers range of solutions, with different % of SiC, different grain size (from fine SurBond SC-series and Buffalo Patch to coarser Onyx mortars) and different setting times, including mortars air-setting within 6-8 hours. Based on customer requirements, Vesuvius technical experts would recommend a suitable solution.

Water-based graphite anode coating

Elekote II is a ready-to-use water-based graphite coating for anodes. It has improved suspension characteristics that allow it to be used in Pot Room operations.

Product Benefits:

Increases electrical conductivity between the anode stub and the cast iron thimble.

Reduces total cell voltage loss and improves cell performance.

Increases the removal efficiency top return thimbles used in the pot room.

Do you have questions about Vesuvius products for potlines? Any other questions? Contact us.