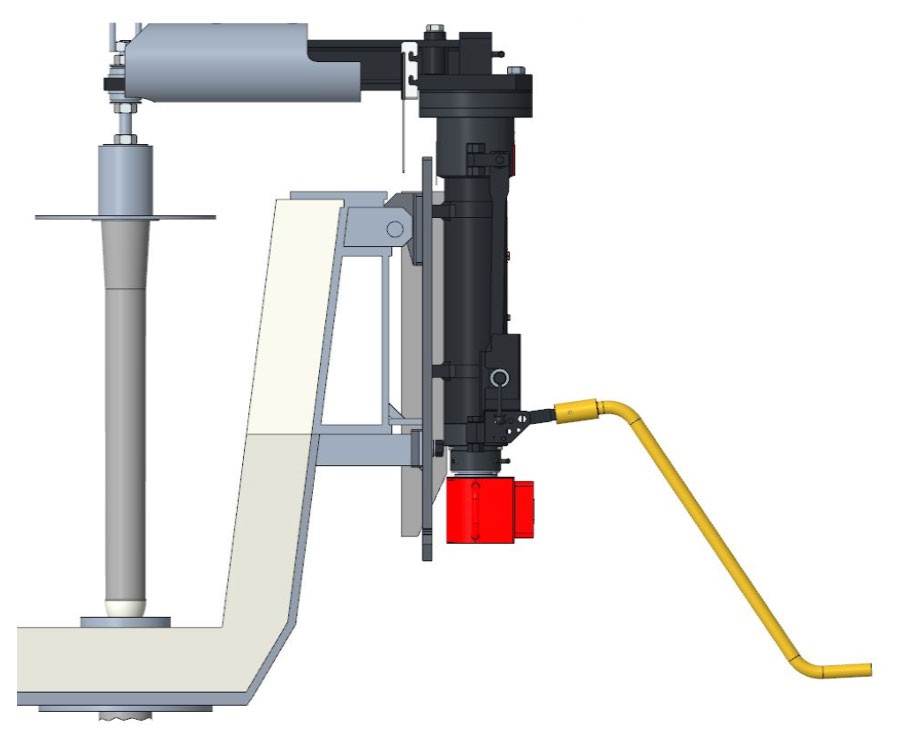

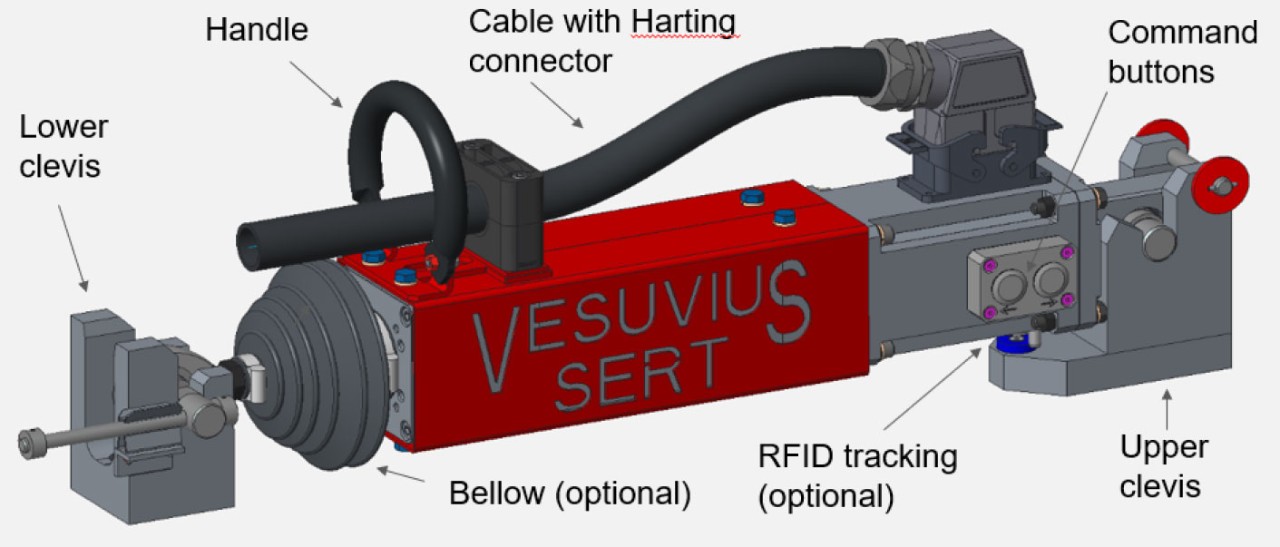

C-Type

High precision electric stopper flow valve

The C-Type electric stopper valve improves enhance features of M-Type with higher velocity, closing force and extended anti-clogging features

Impact of C-Type electric stopper valve

- Utmost mold level stability through ultra fast response time

- Safe casting operation by 100% electric solution (no hydraulic)

- Smooth flow control through real in-line backlash-free and precise guiding

- Performance consistency all year long by heavy duty parts and design

- Ultra low maintenance requirements supported by RFID tracking solution

- Fast Return of Investment by thoroughly technology excellence

| Stopper rigging type: | M-Type | C-Type (new) |

| Linear speed: | 100 mm/s | 300 mm/s |

| Continuous force: | 0.37 T | 0.69 T |

| Stopper closing force: | 0.7 T | 1.4 T |

| Actuator weight | 14 Kg | 13 Kg |

| Time for axis greassing | 6 hours | 15 mins |

Why should you choose Vesuvius’ Stopper Valve?

- Improved performances with higher velocity

- Increased precision of stopper position through rigid guiding design

- Safe closing with increased closing force (1.4T instead of 0.7T)

- Reduced down time with very fast greasing (no more dismounting of axis)

- User friendly stopper adjustment (arm remains horizontal)

- No more adjustment needed with build-in anti-rotation of rigging axis

- Extended anti-clogging features with increased dithering range

- Optional dither friendly manual lever with uncoupling

Test bench for stopper mounting or maintenance

In tundish preparation area:

- Easy stopper position adjustment

- Automated test procedure

In maintenance workshop:

- Advanced diagnostic tool

- Automated test procedure

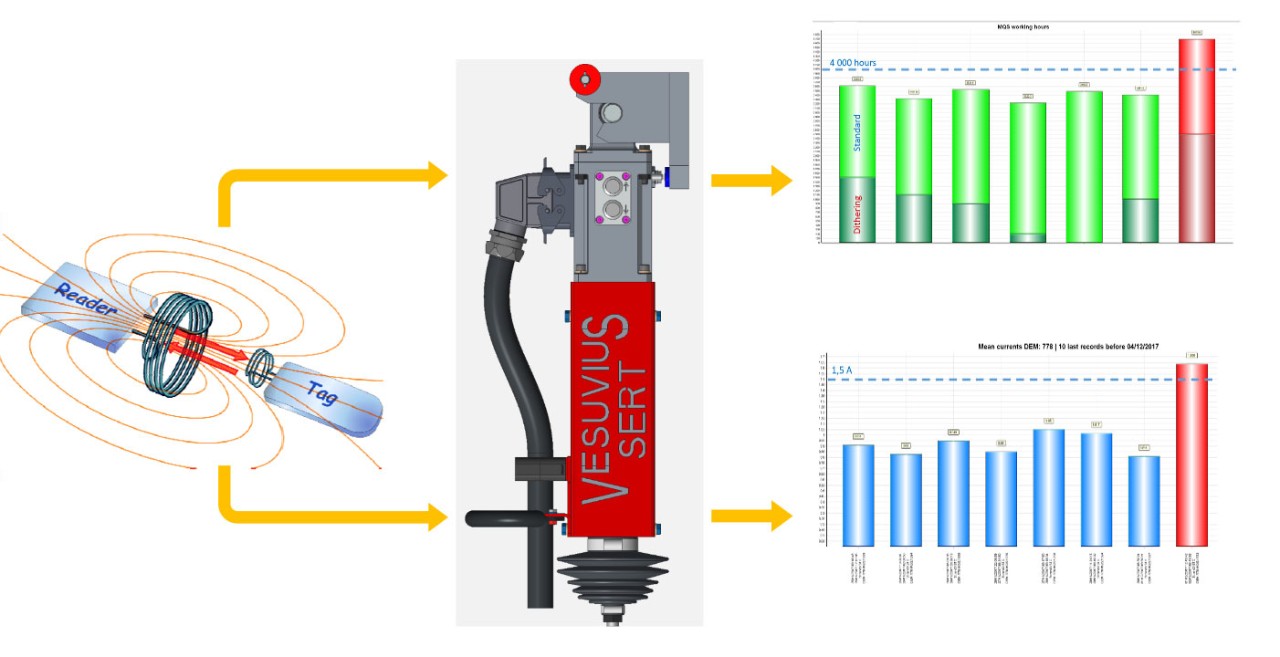

Preventive Maintenance through RFID tracking

Unique identification (Serial number)

- MQS mechanism

- DEM9M actuator

Continuous data harvesting:

- First date of operation

- Operation hours

- Maintenance history

- Operation values: time & current

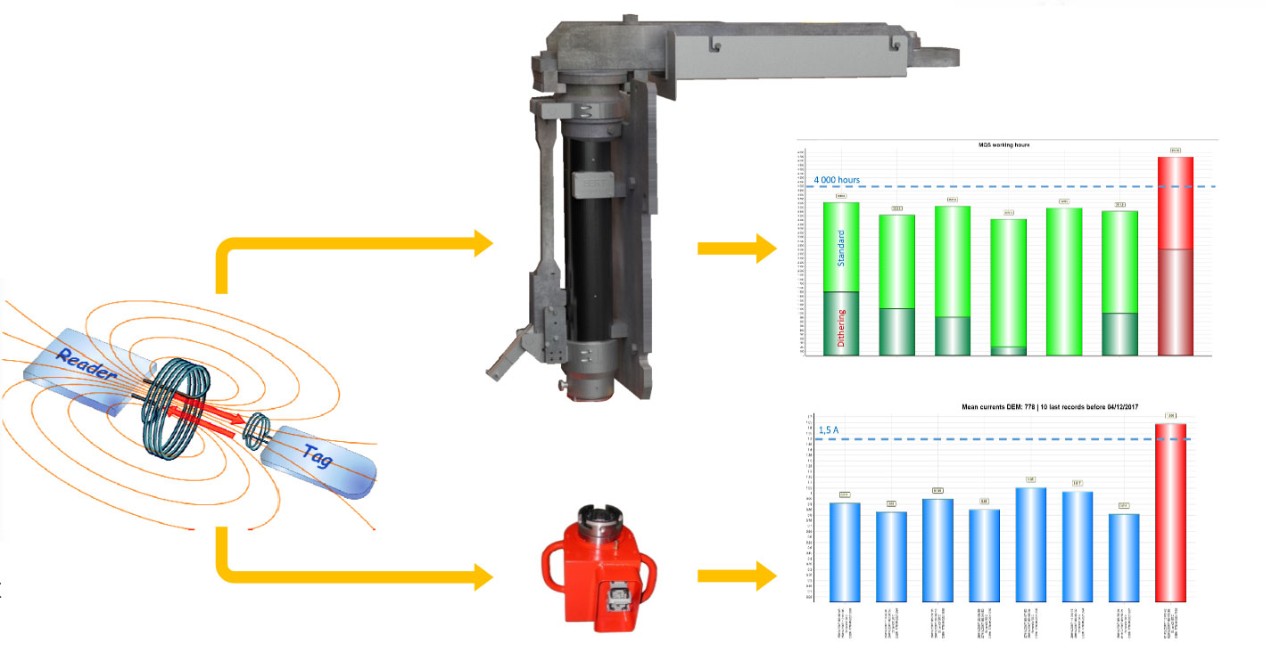

DEM9A

Fast and accurate electric servo-actuator

The DEM9A servo-actuator offers the possibility to convert most of the riggings available on the market to electric actuation for better flow control consistency

- Improved performances with higher speed x3

- Safer closing with higher closing force x2

- Predictive maintenance with RFID tracking (new)

- Extended dithering range

- No risk of over heating

- UPS option for safe closing

| Actuator type: | DEM9B | DEM9A (new) |

| Compatible driver: | ACV9BP | ACV9BP (400V) |

| Linear speed: | 100 mm/s | 300 mm/s |

| Continuous force: | 0.35 T | 0.80 T |

| Peak force: | 0.59 T | 1.13 T |

| Weight | 23 Kg | 18 Kg |

| RFID tracking | No | Yes |

Test bench for stopper mounting or maintenance

In tundish preparation area:

- Easy stopper position adjustment

- Automated test procedure

In maintenance workshop:

- Advanced diagnostic tool

- Automated test procedure

Preventive Maintenance through RFID tracking

Unique identification (Serial number)

- MQS mechanism

- DEM9M actuator

Continuous data harvesting:

- First date of operation

- Operation hours

- Maintenance history

- Operation values: time & current