Description:

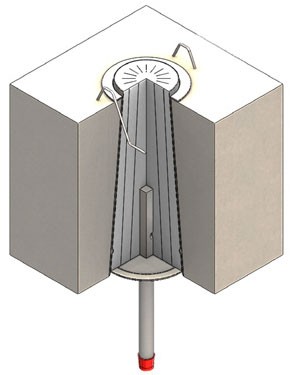

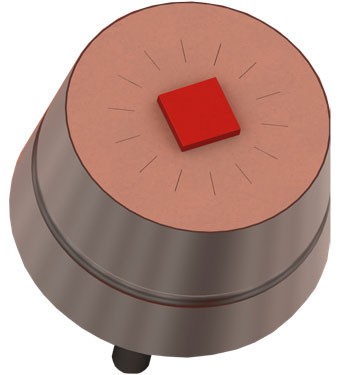

- OptiClean is a high performance porous core purge plug for ladle application.

- It produces fine argon bubbles with multi-directional flow.

- Dedicated to customers looking for improved opening efficiency and reduced oxygen cleaning (lancing) of the plug after use.

Benefits:

- High opening efficiency - very little to no oxygen washing

- Enhanced mixing at low flow rate

- Increased operational safety

Purge Plug Product Range

Vesuvius offer:

A wide range of Purge Plugs for different steel plant demanding applications:

- High Opening efficiency

- Wide rage of flow

- Small bubbles for clean steel (OptiClean)

- Vigorous stiring for process optimization (OptiFlow)

Our solutions support our customer process:

- Desulfurization

- Reduction of non-metallic inclusions

- Uniform distribution of temperature and alloy additives

- Steel cleanliness

Vesuvius brings the appropriate plug design to perfectly balance bubble volume, size and flow rate, combined with all needed ancillaries, including user-friendly and safe setting systems.

Related Solutions

Vesuvius Ladle Purging Solutions combine top quality material, optimum design and on-site experienced service, with practical support of our different teams, to bring to our customers:

- safer operation with optimized wear indicators

- wear resistant Housing Block designs to cope with high local turbulencec

- Plug and Block Assemblies (PBA) :

- factory fitted assemblies guaranteeing a uniform mortar joint

- reducing installation variables and risks on site

- high performing castables and pressed products

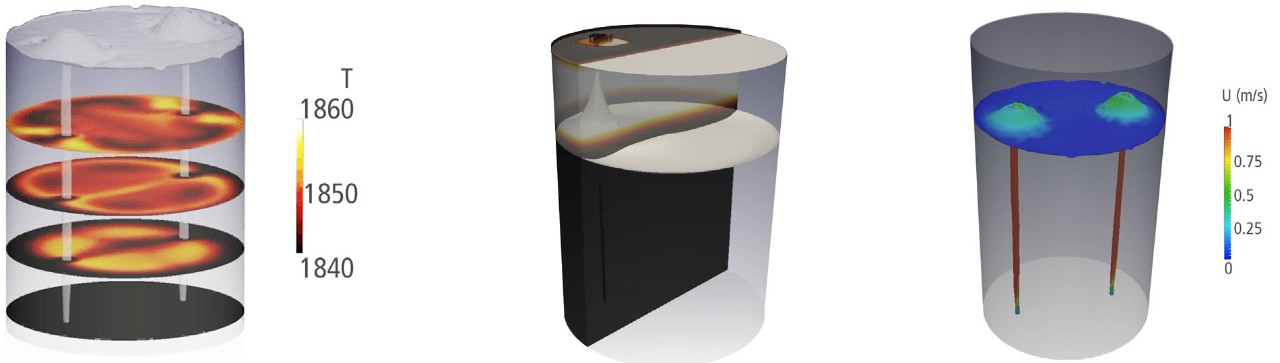

Our innovative and highly experienced Flow Simulation team has helped in developing customized solutions using combination of CFD (Computational Fluid Dynamic) analysis and Physical Modelling.

Housing block

Plug / Block assembly

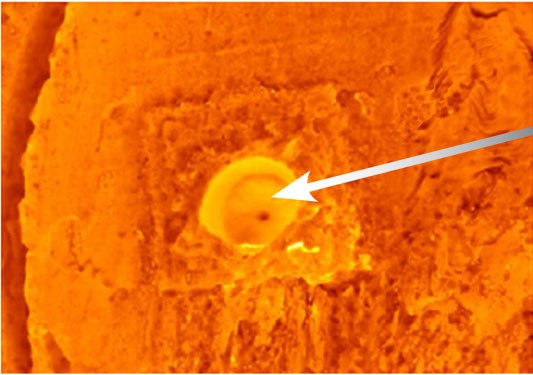

Wear indicator

Reliable wear indicator visibility for consistent decision making

Our innovative and highly experienced Flow Simulation team has helped in developing customized solutions using combination of CFD (Computational Fluid Dynamic) analysis and Physical Modelling.

Research & Development and Service

- Continuous Research and Development

- Computational Fluid Dynamics (CFD) Analyses the optimized plug position, plug amount and flowrate requirements for

- Reduced wall shear stress

- Improved chemical and thermal homogenization

- Meniscus deformation

- Water modelling facility

- Purging systems design team

- Installation, commissioning and ongoing technical support

Purging Function

| Temperature adjustment: | 1000 - 2500 l/min |

| Temperature and chemical homogenization: | 200 - 1000 l/min |

| Desoxidation and adjustement of hydrogen Content during vacuum tank degassing: |

50 - 200 l/min |

| Non metallic inlusion removal: | 10 - 50 l/min |