PDM300 – Powder Distribution Mechanism

The new PDM300 is a state of the art Mould Powder Distribution Mechanism to precisely adjust and deliver granulated powder at the desired rate into the mould.

Main features

- Purchase of the best quality raw materials;

- Adapted for slab and bloom moulds

- Continuous delivery of granulated powder in the mould

- Adjustable mass flow rate control

- Provides real-time powder consumption for each discharge line

- Anticipated buffer draining for fast powder change

- Automatic unclogging of the discharge lines

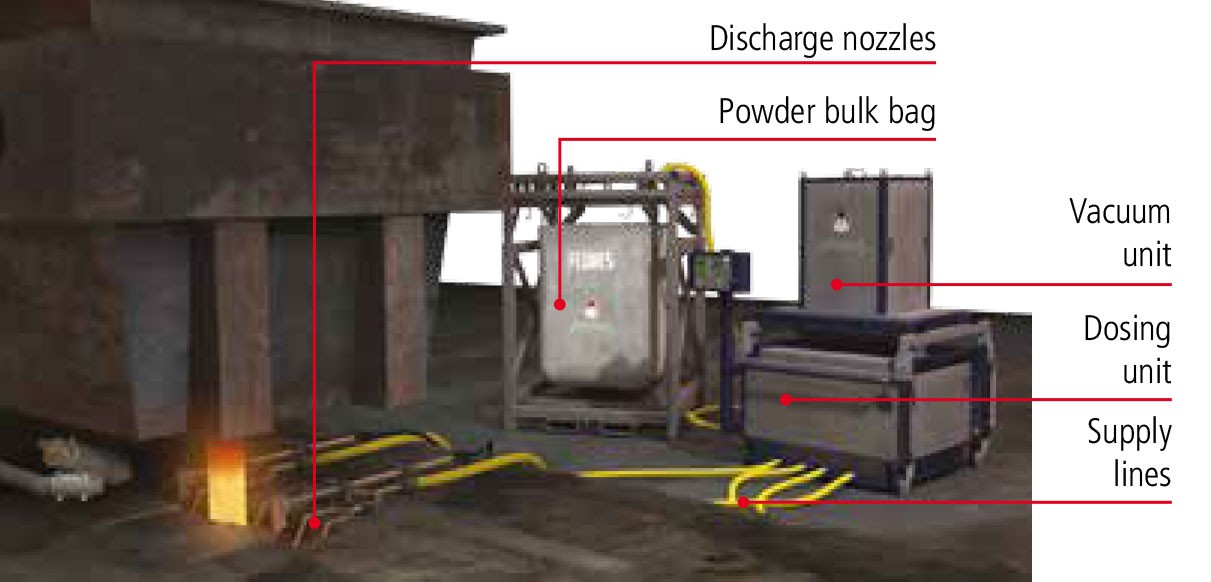

PDM300 - Vacuum version

The PDM300-Vacuum version uses a vacuum unit to aspirate the granulated powder from a remotely located bulk source (bulk bag or silo).

Typical installation layout

Control

Touchscreen HMI for parameters setting

Wireless remote pendant for setting of powder discharge rate

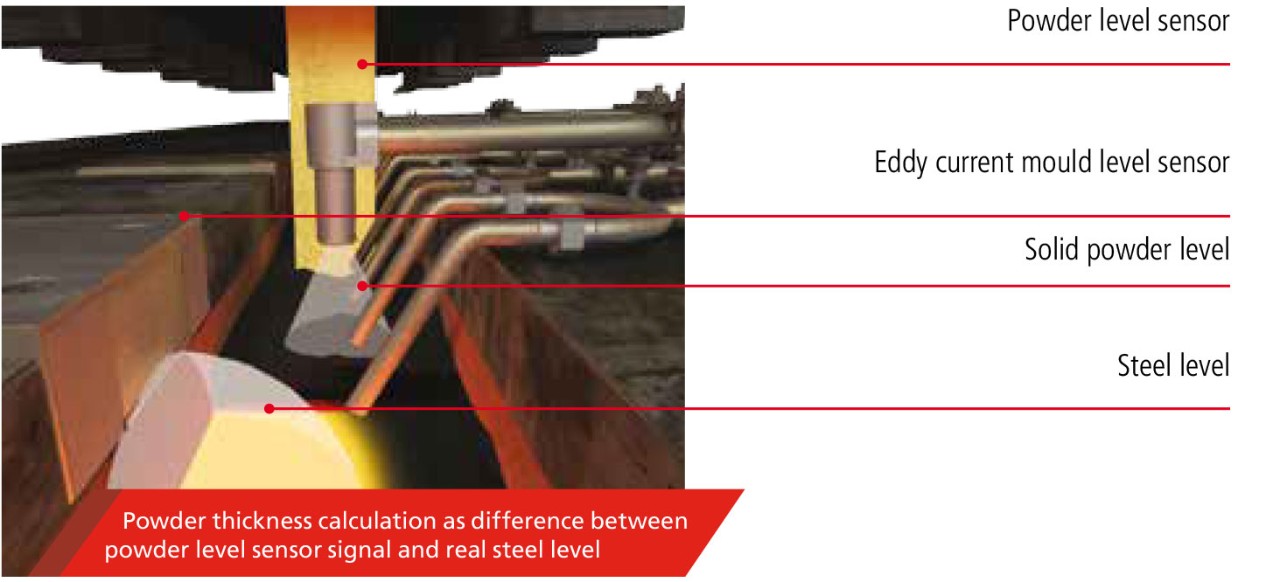

Powder Level Sensor

It measures the top level of granulated powder in the mould.

Main features

- Mounted on discharge nozzle, tundish car or dedicated support

- Signal accuracy not affected by dust or flame

Example of installation

Powder Level Control

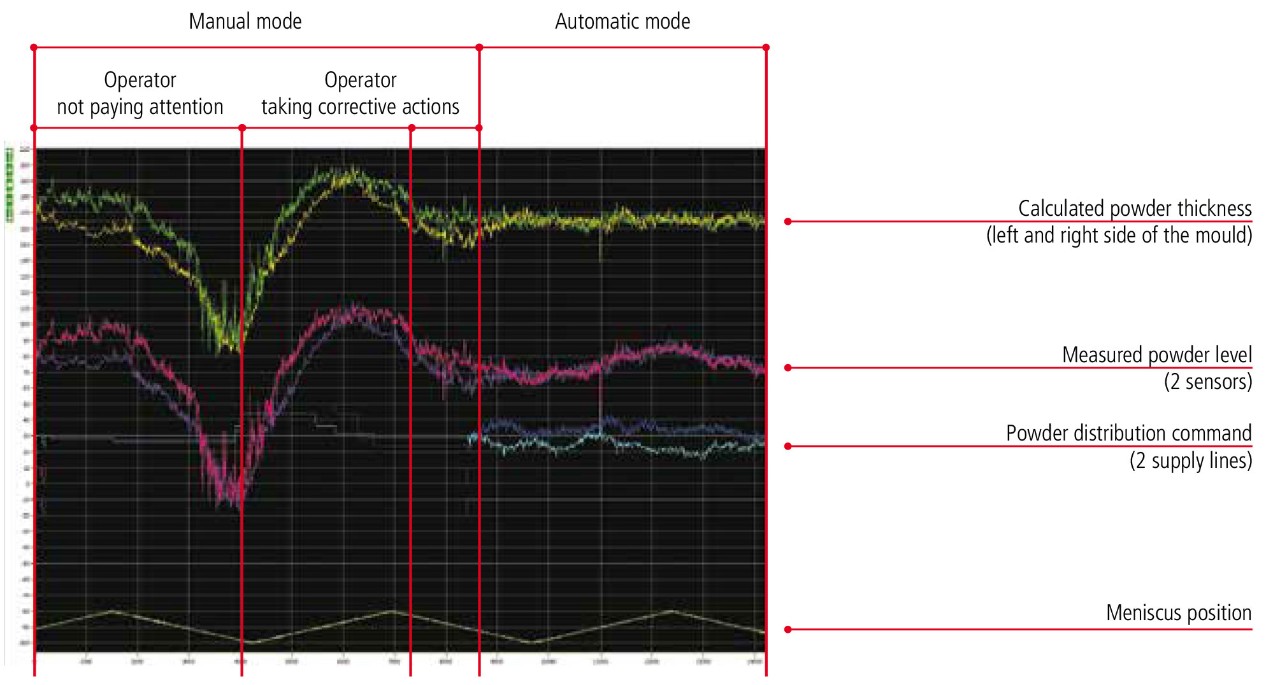

It is a PLC based controller, designed to control and optimize the granulated powder thickness in the mould. It uses DASCO computer to provide data storage and analysis of mould powder control parameters.

Main features

- Powder thickness control

- Remote control via ethernet and communication with level 2 computer

- Data storage and analysis

DASCO screenshot: Smart Powder Distribution Control during one sequence (4 hours)

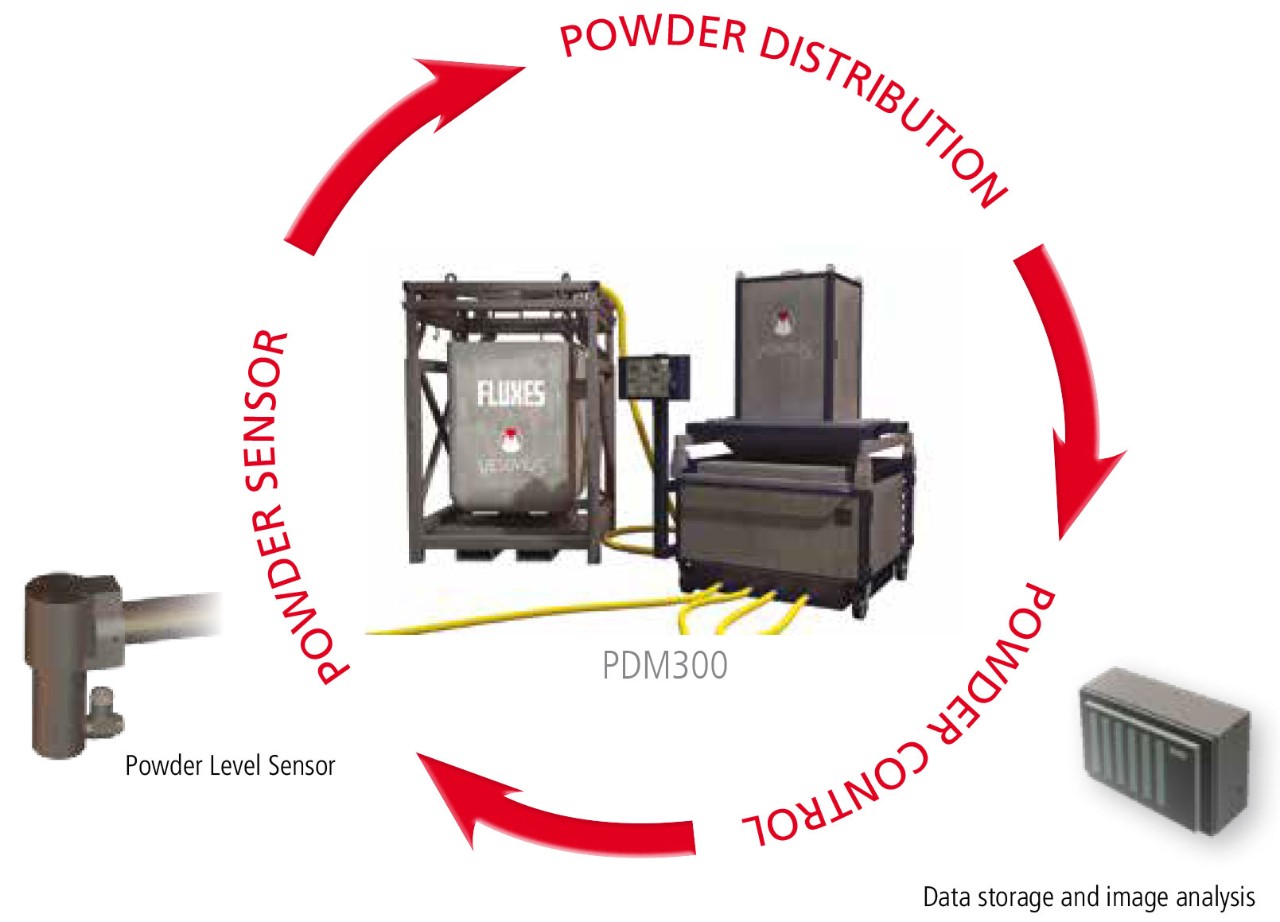

Smart Powder Distribution Mechanism

Vesuvius offers a global solution for automatic distribution of granulated casting powder into the mould.

The smart powder distribution mechanism consists of

Powder Distribution Mechanism

- PDM300 - Powder Distribution to precisely adjust and deliver granulated casting powder at the desired rate into the mould.

with its key elements:

- Powder Level Sensor to measure the top level of granulated powder in the mould.

- Powder Level Control to optimize the thickness of granulated powder in the mould.