What is BASILITE QuickStart?

BASILITE QuickStart is a tundish working lining spray mass that has been developed by Vesuvius as a rapid drying technology. It allows teams to totally bypass or significantly decrease the drying cycle and move the tundish faster to the CCM preheating station.

Better than the old ways

Traditionally, when a spray mass is applied on a tundish, it requires 3 to 7 hours of primary drying cycle on 500-700ºC. For this reason, tundish needs to be sent to the allocated drying area, which sometimes is far away from the preparation area. Only then can the tundish be moved again to a CCM preheating station for the start of the molten metal casting sequence.

Cutting-edge technology

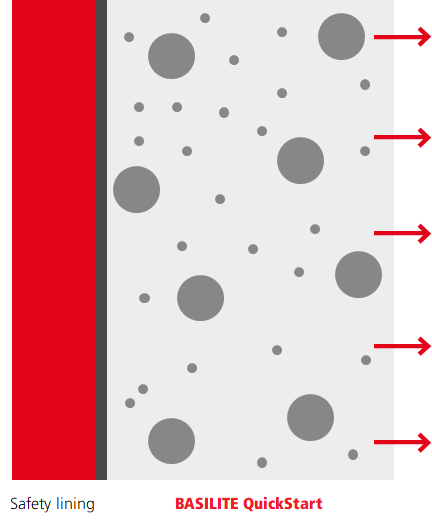

BASILITE QuickStart utilizes an engineered microstructure that facilitates free emission of water vapor without the dry-out phase. Improved green strength and adhesion minimizes risk of wall collapse. In addition, BASILITE QuickStart mix demands much lower water percentage than any other spray product in the market.

Technical details of BASILITE QuickStart

- Developed engineered microstructure that enables the free emission of water vapor without the Dry-out Cycle.

- Improved green strength and adhesion neutralizes the risk of wall collapse.

- BASILITE QuickStart formula requires much less % of water in comparison with all the other products in the market.

Product Performance Drivers of BASILITE QuickStart

The three-dimensional efficiency indicator:

Gas/Energy Efficiency

- Minimalization of energy consumption compared to other solutions available on the market

- Lower Energy Costs

Operational Efficiency

- Increased Tundish availability and debottlenecking of tundish preparation cycles

- Improved productivity in Tundish Bay by 20-50% depends on the customer

- Simplify the flow in Tundish bay layout (absence of the steps to/for the Dry-out area

- Absence of Dry-out equipment and maintenance of the same

CO2 Emission Efficiency

- Reduced CO2 emissions

- Contribution to the „Green Steel” concept

- Significant improvement of the LCA/LCM measures at steel mills

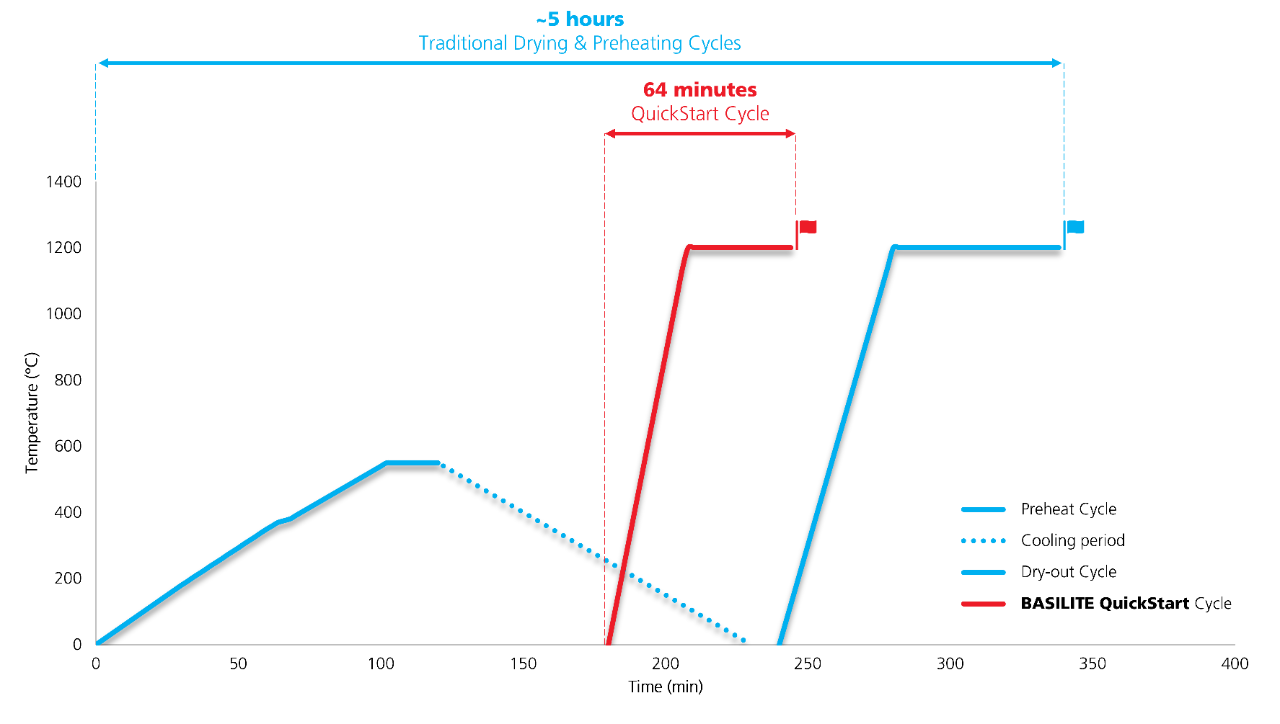

Comparison: Dual Heating Cycles vs. single QuickStart Cycle

Traditional Dual Drying & Preheating Cycles

Traditional cycle: ramp up the temperature to 982 – 1316° C as soon as possible and then hold it there for over 2 hours

New, single QuickStart Cycle

QuickStart Cycle: single Heating Cycle in 60 minutes and then directly to casting.

Vesuvius Efficient Tundish – Benefit Variables Summary

Key features

- Vesuvius rapid drying QuickStart technology

Benefits to the Customer

- Increased Tundish availability

- Improved productivity in Tundish Bay

- Simplify the flow in Tundish bay layout (absence of the steps to/from the dryout area

- Absence of Dryout equipment and maintenance of the same

Environmental Benefits

- Reduced energy wastage

- Reduced C02 emission

How can QuickStart technology help you?

Thanks to Vesuvius QuickStart technology, our customers achieve:

Increased Tundish availability

Energy savings

Reduction of CO2 emissions

Improved productivity in Tundish Bay

Simplified flow in Tundish Bay layout by omitting the dry-out area

Absence of dry-out equipment and maintenance of the same

Improved working lining surface with the absence of cracks

Benefits of BASILITE QuickStart Cycle

Time Savings

- Increase tundish availability - the additional, typical 2-6 hour drying cycle is not needed

- Preheat cycle times can be reduced

Time Savings

- Increase tundish availability - the additional, typical 2-6 hour drying cycle is not needed

- Preheat cycle times can be reduced

The BASILITE QuickStart to concrete lining interface temperatures are very similar after the 63-minute fast fire heating cycle compared to that achieved after the preheat of the traditional dual heating cycles (all water is removed).

Trials of BASILITE QuickStart

Transform your Tundish Bay.

For environment, for operations, for business.

Trials with BASELITE QuickStart spray can be arranged and tailored to a customer’s CCM preheat stations to evaluate and realize the potential benefits in a customer’s Tundish Bay. Vesuvius experts with project approach will monitor to find the “sweet spot” of the QuickStart cycle for your plant.

The Vesuvius Efficient Tundish technology is the best for production; reducing cycle times, reducing energy waste and reducing the impact on the environment while speeding up production and operations.

It’s a win-win for everyone.