What is SURCAST QuickStart?

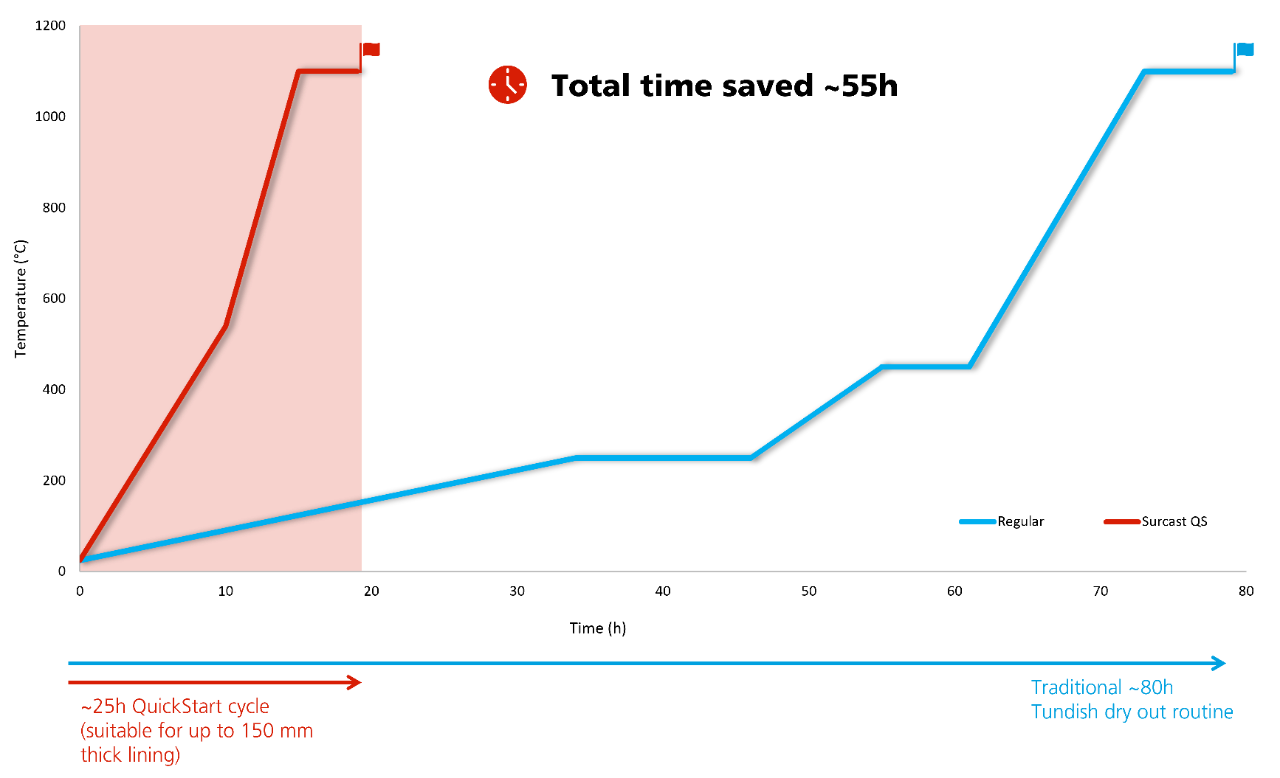

- Traditionally, preparing a Tundish backup lining typically takes about a week. Once cast, the lining requires approximately 24 hours for air curing.

- Subsequently, it undergoes a heating process with variable rates, starting from 20-30°C per hour until reaching the terminal temperature.

- SURCAST QuickStart is a specialized castable Tundish safety lining developed by Vesuvius for a rapid heating cycle known as the ‘QuickStart’ heating cycle.

- The Tundish with a SURCAST QuickStart lining can be heated at a rate of 50°C/h till 540°C and then at 100°C/h until the highest temperature, depending on equipment availability.

- This lining can be ready within ~25h and can, therefore, undergo severe thermal curing cycles.

Customer requirements:

- Reduced Tundish Shell Temperature

- Homogenised steel temperature

- Increased steel volume in tundish

- Stabilised thermal cycling

Vesuvius recommendation:

Introducing our premium SURCAST QuickStart –

Energy Efficient Tundish Safety Lining designed to reduce

the amount of material Energy wasted during processing.

SURCAST QuickStart castable key features:

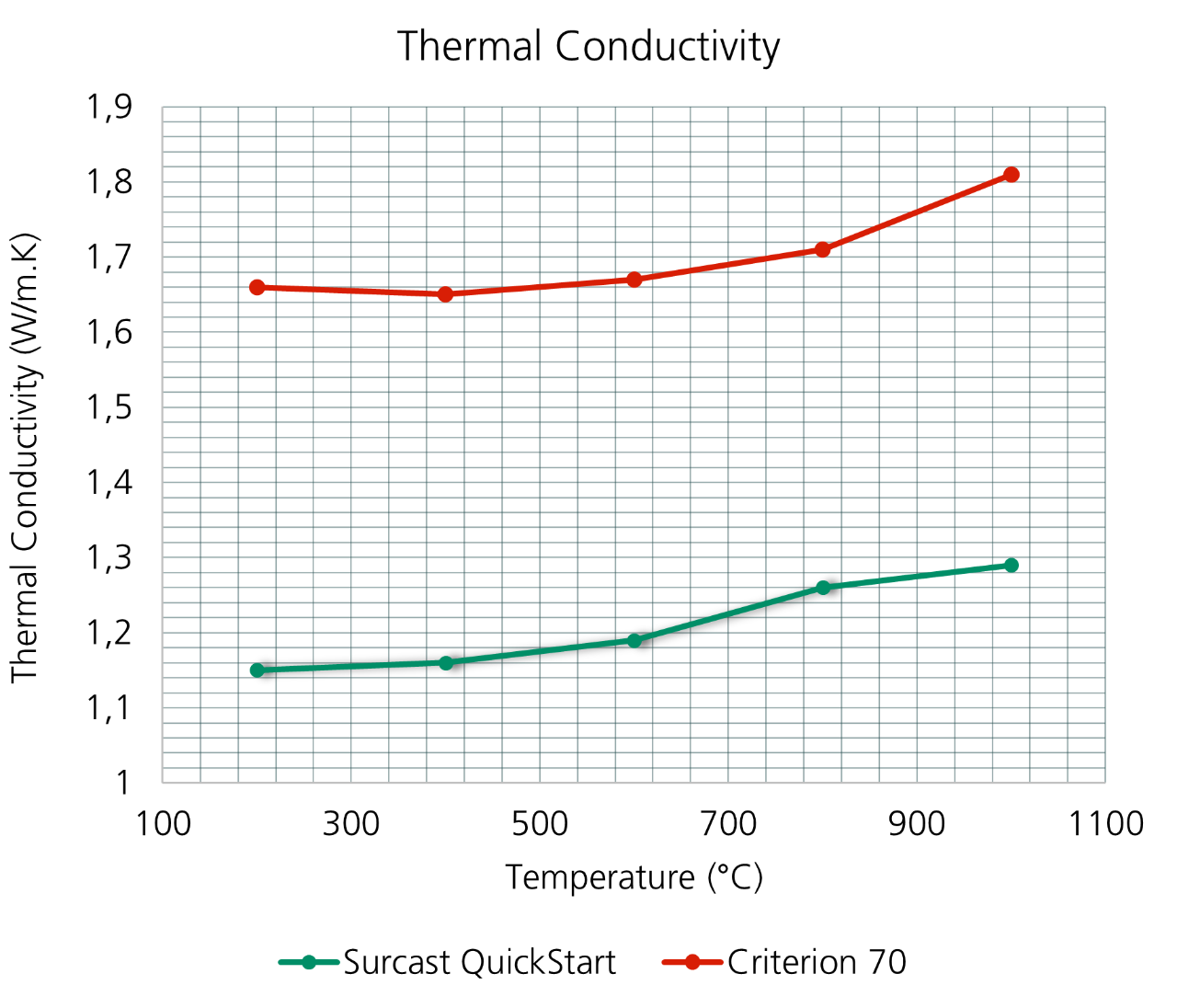

- A 25% reduced thermal conductivity

- Vesuvius rapid drying and QuickStart technology

- Excellent safety slag-line erosion and corrosion resistance

Total cycle time

Thermal Conductivity - Maintain the SUPERHEAT in Tundish

The lining made with Surcast QuickStart is designed to reduce the shell temperature drop.

The tundish preheating time can be reduced as the heat is contained ‘within.’

The maintain of superheat in tundish reduces the risk of steel freezing conditions.

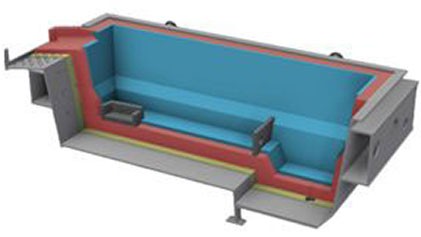

Application: tundish safety lining

- Can be used as a vibratable concrete (5.5 – 6.0% water) or as a self-flow (6.0-6.5 % water).

- Can be used with current insulation bricks/panels to improve insulation i.e. better maintain tundish steel temperatures / potentially lower ladle superheat temps, main recommendation…or,

- Used with no / less insulation to maintain current tundish temps / superheat temps and save on material insulation costs and time.

Potential benefits

to the customer:

Lower tundish shell temperaturę

Increased available tundish volume

Improved tundish turn around time

Absence of melt cold spots

Good chemical stability

Excellent thermal stability

Vesuvius recommendation:

Reduced Energy wastage

Reduced material wastage

Reduced installation time and improved health and safety conditions for the tundish working crew

SURCAST QuickStart Benefits

Key

Features

@ 25% reduced thermal conductivity

Vesuvius rapid drying and QuickStart technology

Excellent safety slag-line erosion and corrosion resistance to date

Benefits

to the Customer

Lower tundish shell temperature

Increased available tundish volume

Improved tundish turn around time

Reduction of melt cold spots

Good chemical stability

Excellent thermal stability

Environmental

Benefits

Reduced energy wastage

Reduced emissions

Rapid-fire tundish safety lining castable. Developed to save time, costs and energy.