What is Turbostop?

A patented tundish flow control system used in the impact area of a continuous casting Tundish. Custom designed and engineered for each caster by Water Modelling and Computational Flow Dynamics.

- Dampening the energy of the incoming stream, suppressing turbulence in the pour

- Upward flow eliminates short-circuiting of the steel through the tundish, giving a more controlled steel flow

Key features

Turbostop is installed in the impact area of the Tundish, directly beneath the Ladle Shroud pouring stream.

It works by dampening the energy of the incoming stream, thus suppressing turbulence in the pour area.

The resultant upward flow eliminates short-circuiting of the steel through the Tundish, giving a more controlled steel flow

Benefits of Turbostop

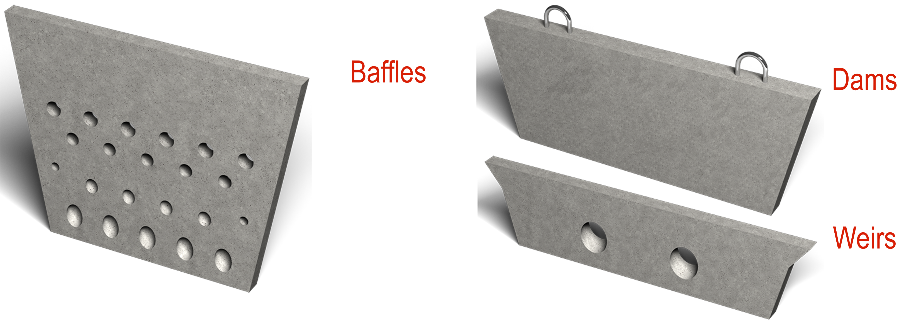

Precast shapes designed to change the flow of liquid steel through the Tundish:

- Reduce velocity

- Dampen turbulence

- Create pooling to maintain ferrostatic head

- Even steel flow to multiple nozzles

- Enhance capture of inclusions

Individually designed for each Tundish using CFD.

@2x.png)