Excellence in hardware, software and service

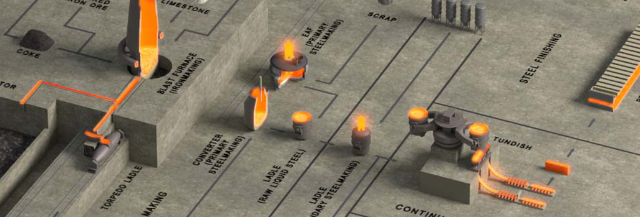

Steel plants and other metal producing facilities are large and capital-intense companies competing in the worldwide market. This highly competitive environment demands seamless operations and full control over the processes. Process Metrix solutions provide the tools which allow engineers and operating personnel to make decisions based on quantitative data, where previously, experience and naked eye measurements were the only options.

Vesuvius’ products provide remaining refractory thickness in any metallurgical vessel with highest accuracy. The ANTERIS laser scanner product line provides unique features and exceptional integration in our customer’s facilities.

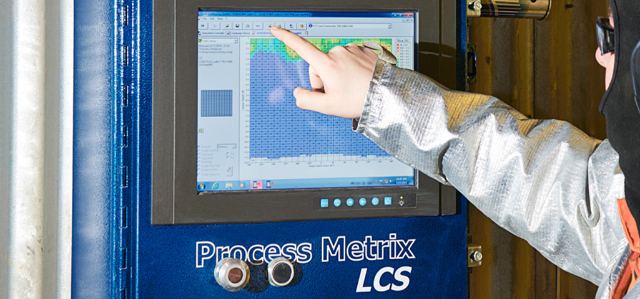

ANTERIS is paired with our own State-of-the-Art HYPERION software suite, offering not only the best performance in the business but also unparalleled integration possibilities.

Our customer focus culture and historical worldwide presence offering one of the most comprehensive support networks in the industry. Our customers appreciate experiencing our service-minded and customer-centric culture before, during, and long after the project is complete.

Join them: use Vesuvius solutions to help yourself become a more efficient facility!

Laser Contouring Systems

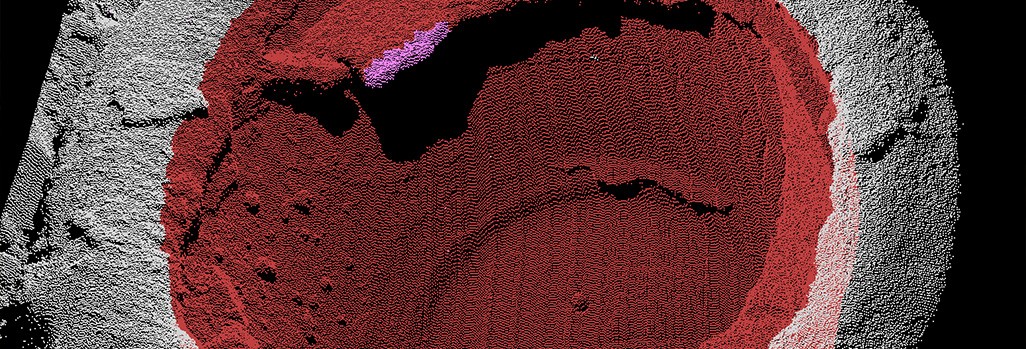

Laser contouring systems are devices designed to measure the remaining thickness of refractory left in the lining of a metallurgical vessel. Its functional benefits include the following:

Safety: Prevent total loss of refractory in any area, which could result in potentially catastrophic loss of containment of the molten metal.

Productivity: Safely assess the remaining lifetime of the refractory lining and adjust its service life accordingly.

Efficiency: Allow precise refractory repair by targeting only the areas of highest wear for gunning/spraying, saving material and time.