Introduction

Vesuvius Process Metrix is a worldwide technology leader specializing in laser measuring solutions for the global metal industries. The company focuses on controlling refractory wear in hot vessels for steel as well as various other metallurgical operations, and on providing advanced solutions to support the industry in optimizing its process. The Company is a critical partner to major steel producers across the globe.

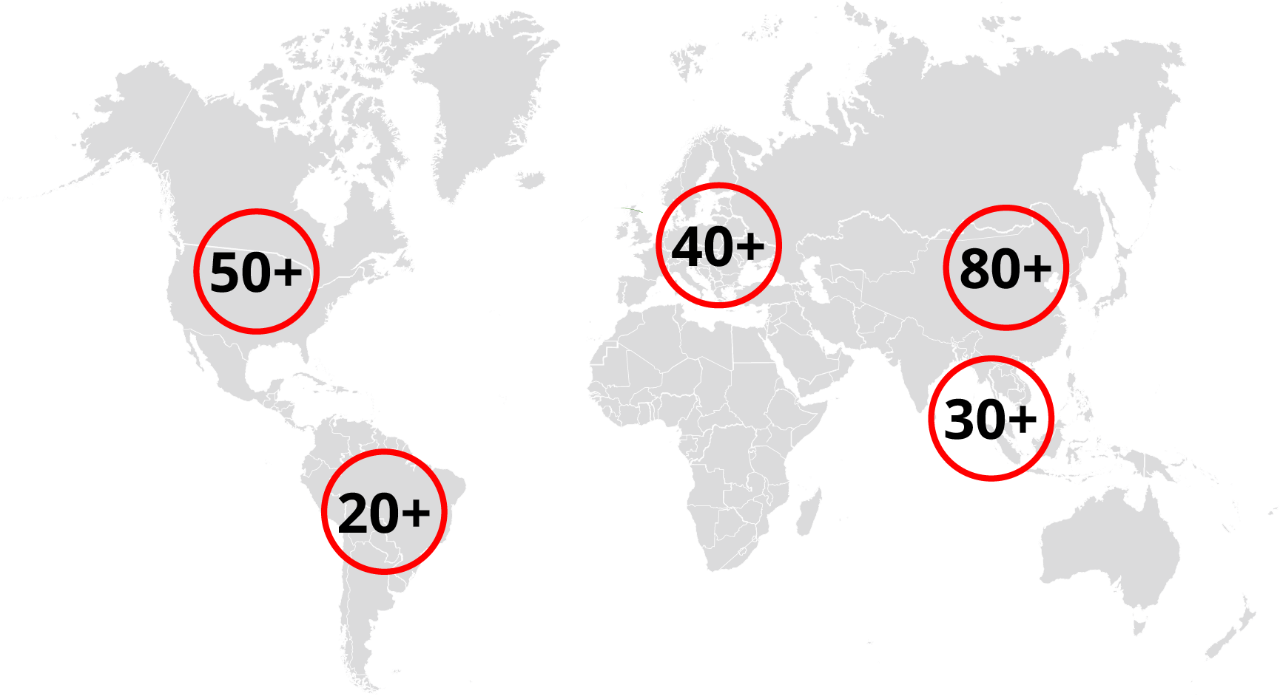

Global Market Presence

With a worldwide presence, Vesuvius Process Metrix maintains a strong and expanding installed base across key markets. The company has established solid footprints in the Americas and North Asia, with growing presence in EMEA and developing operations in South America and South Asia. Its prestigious client roster includes industry leaders in steel production across multiple continents.

An installed base in continuous expansion

Technical Excellence and Innovation

The company's strength lies in its talented engineering team of professionals specializing in mechanical, electrical, electronics, and software engineering. Vesuvius Process Metrix develops purpose-made solutions exclusively for the metallurgical industry, utilizing Microsoft Windows-based software, advanced 3-D CAD development tools, and Finite Element Analysis (FEA). Each instrument is assembled in the company's factory and undergoes rigorous quality control testing and verification.

Product Portfolio

Hardware

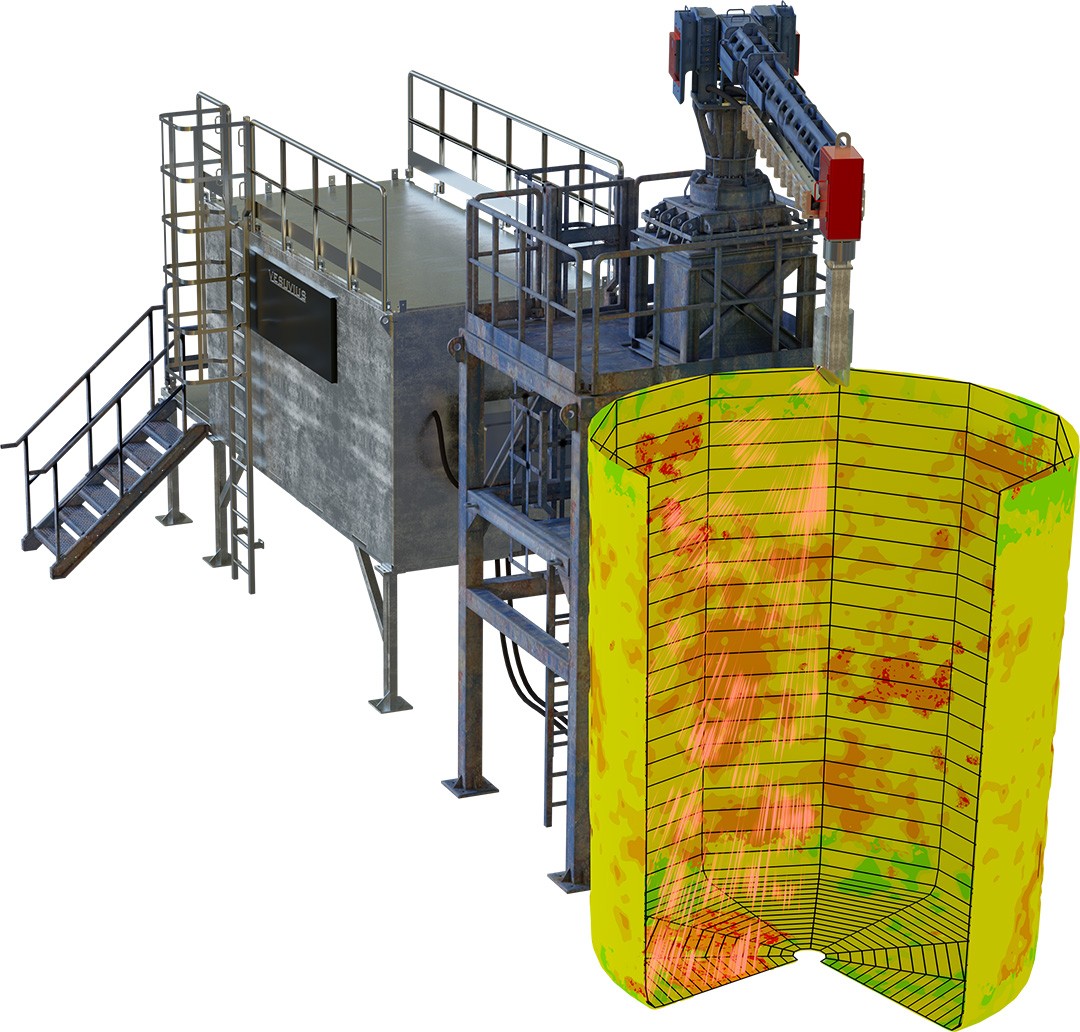

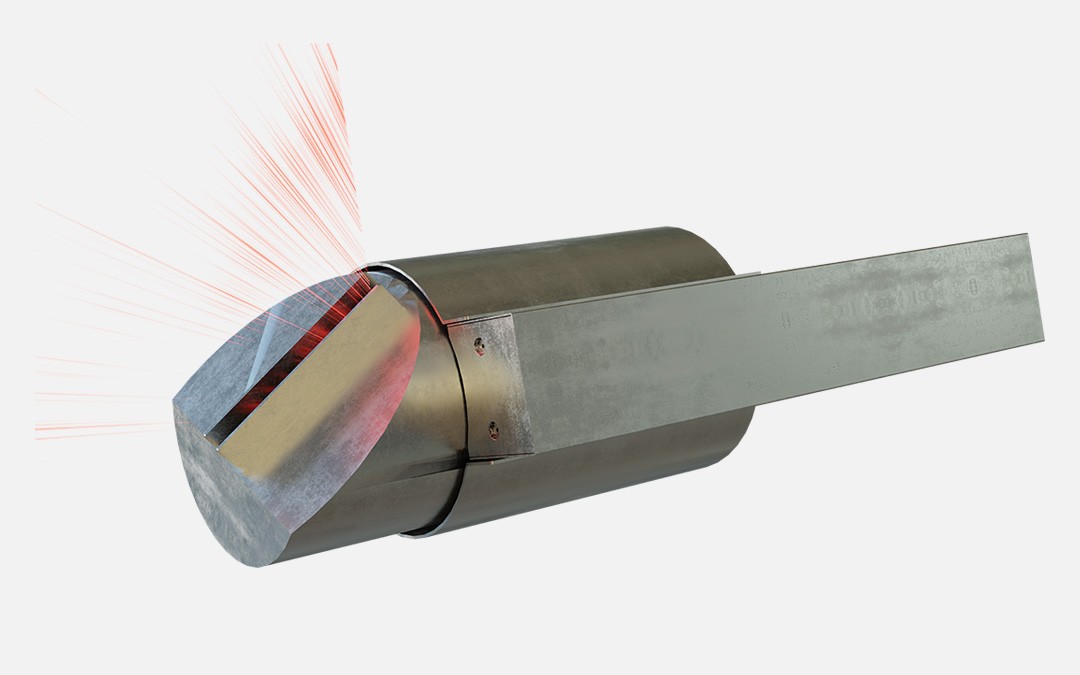

The company offers three main product lines through its ANTERIS* hardware:

- Mobile Unit: A pioneering solution dedicated to Basic Oxygen Furnace (BOF) applications

- ANTERIS* 300: A versatile solution for scanning all vessel types including BOF, ladles, and Electric Arc Furnaces (EAF)

- ANTERIS* 360: A cutting-edge solution with enhanced field of view capabilities for comprehensive vessel scanning

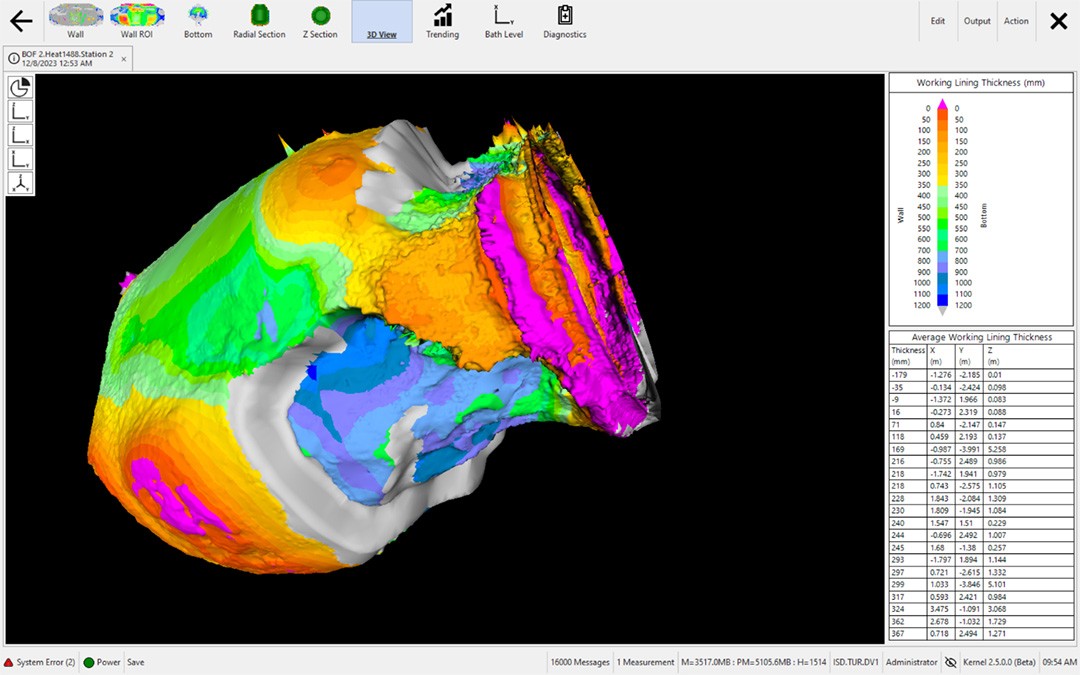

Software

Process Metrix hardware solutions are enhanced by HYPERION* software suite, which offers unparalleled display facilities and plant-wide connectivity in an intuitive interface.

For ladle applications, the LAPs-AI service package offers ladle fleet management as well as predictive capabilities and much more.

Strategic Infrastructure

Vesuvius Process Metrix operates with a centralized engineering hub in Lyon, France, complemented by four spare parts locations (Lyon, Chicago, Kolkata, and Suzhou) and dedicated service centers in the USA, China, and India. The Lyon facility positions the company at the center of its three main markets - USA, Europe, and Asia - while embedding it within a nexus of digital industrial companies.

The Lyon facility brings together three core fields of expertise: opto-electronics, mechanics, and software development. This consolidation has created engineering synergies with Vesuvius SERT, a leader in molten steel flow control, allowing both companies to leverage shared expertise in mechatronics applications, software, automation, and digital technologies for the metal industries.

Vesuvius Process Metrix positions itself as a dedicated partner ready to help metal industry facilities advance to the next evolution in refractory management, combining technological innovation with reliable global service and support.

Key Dates

- Late 1980s - Early 1990s: Established close collaborations with government laboratories, securing $5M in government research funding to advance industrial measurement technologies.

- 1993: Partnership with Sandia National Laboratories to develop advanced instrumentation for the molten metals industry, including two-color pyrometry for bath temperature measurement, spectroscopy for BOF/EAF off-gas control, and laser range finding for refractory thickness measurement.

- Late 1990s: Strategic focus shift to specialize in refractory thickness measurement systems.

- 2001: Secured seed funding from AISI and Vesuvius to develop the first mobile Laser Contour Scanner system, marking the beginning of commercialization.

- 2004: Achieved first international sale to ISDEMIR in Turkey, establishing global market presence.

- 2005: Expanded application portfolio with first Electric Arc Furnace (EAF) installation.

- 2006: Further diversified solutions with first ladle installation.

- 2008: Completed comprehensive redesign of mobile scanning system to enhance performance and reliability.

- 2011: Launched ANTERIS* product line at METEC, introducing a new generation of laser scanning technology.

- 2014: Acquired by Vesuvius, joining a global leader in molten metal flow engineering and refractory solutions.

- 2016: Introduced ANTERIS* 300, expanding capabilities across multiple vessel types.

- 2018: Released ANTERIS* 360 and ANTERIS* 360t, featuring enhanced field-of-view technology for comprehensive vessel scanning.

- 2024: Established new headquarters and engineering center in Lyon, France, creating synergies with Vesuvius SERT and positioning the company within a hub of digital industrial innovation.

- 2025: Opened dedicated Chicago Service Center to strengthen North American customer support and service capabilities.

(*) A trademark of the Vesuvius Group of Companies, registered or unregistered in certain countries, used under license.