What is EAF VARG

Vesuvius Advanced Refractory Gunning (VARG) is a revolutionary robotic platform designed to transform refractory maintenance in Electric Arc Furnaces (EAFs). Traditionally, EAF refractory repairs have been hazardous and time-consuming, exposing operators to extreme temperatures, molten metal, and significant physical strain, resulting in inconsistent application and production losses.

EAF VARG addresses these critical challenges by integrating cutting-edge mechatronics, laser technology, and advanced materials to offer a safe, precise, and highly efficient solution. It shifts refractory repair from a manual, unpredictable task to a repeatable, data-driven workflow, ensuring maximum furnace availability and enhanced safety.

Key Benefits

EAF VARG delivers significant improvements across key operational areas for steelmakers:

Improved Safety

EAF VARG removes operators from hazardous environments, such as extreme heat loads, molten metal splashes, and overhead crane movements. This drastically reduces direct human exposure, minimising lost-time injuries and enhancing overall safety. The system's ability to operate remotely eliminates the need for manual handling of heavy gunning equipment.

Increased Productivity and Efficiency

- EAF VARG enables hot repair, significantly minimising downtime associated with traditional refractory maintenance that requires cooling and shutdown.

- It offers high-speed application rates of over 200 kg/min, with documented speeds of 180-200 kg/min during regular usage at one of our customers and a record 243 kg/min in BOF trials. This high throughput means less time gunning and more time making steel.

- A single operator can manage the robotic gunning process, compared to three operators for manual gunning, freeing up personnel for other high-value tasks.

- Customer case studies demonstrate increased production, with one EAF furnace running 15-20 heats between drains (up from 12-16 heats), resulting in a ~25% increase in heats and 50 fewer drains per year. This can translate to millions of euros in increased earnings.

Extended Refractory Life and Cost Efficiency

- The system allows for gunning ONLY areas that need repair, ensuring precise and uniform refractory application. This reduces gunning material consumption by up to 30% in non-critical areas, resulting in significant cost savings.

- It promotes consistency and repeatable gunning application across shifts, leading to longer campaign lives and reduced frequency of full refractory relining. One customer experienced an increase in brick life from 700 to 930 heats (a 30% increase), and another from 450 to 730 heats (a 62% increase).

- Burn-throughs have decreased to almost nil due to the laser's ability to identify weak areas, allowing for necessary repairs.

Data-Driven Decisions (Industry 4.0 System)

EAF VARG utilises an integrated software system that supports Industry 4.0 principles. It performs fast laser measurements to generate 3D wear maps and automatically generates customer reports on material consumption, gunning time, gunning rates, and water usage. This provides steel shop refractory managers with 100% clarity of consumption data 24/7/365, enabling predictive maintenance and optimised repair protocols.

Automation Levels

- Fully Automatic (EAF VARG): This version offers full functionality with wireless remote control and fully automatic gunning to worn areas. It integrates a PMC laser scanning system for precise measurements and automated gunning sequences, enhancing precision and reducing maintenance costs and downtime.

- Semi-Automatic (EAF VARG): This mode enables operators to set up the machine and initiate or supervise gunning cycles, utilising pre-defined or programmable sequences. It provides flexibility without sacrificing accuracy, enabling safer, faster manual touch-ups in known weak spots.

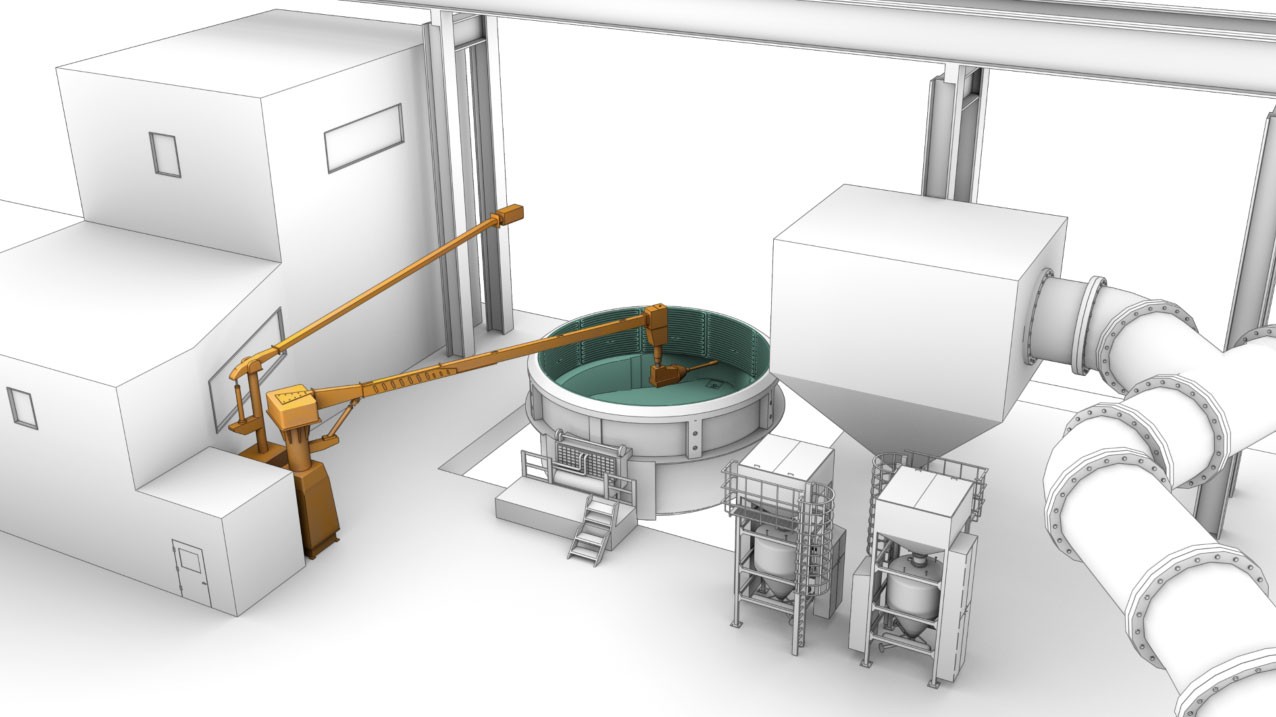

Entry Configurations

- Top Entry

This is the most common form of manipulator access, entering through the roof of the EAF. Key Features: Servo-controlled, highly precise movements, and only one basement for both the gun arm and laser arm, ensuring a compact footprint. - Slag Door Entry

This configuration allows for gunning through the slag door.

Key Features: Offers more energy saving by not opening the EAF roof during gunning, leading to increased EAF availability.

Core Technologies

- ANTERIS 360™ / 300™ Laser Contouring System: This state-of-the-art laser system captures over 1 million data points to create a high-resolution 3D model of the furnace's interior in under 60 seconds. It precisely identifies wear hotspots, skull build-up, and cracks, guiding the robotic repair.

- Twin-Tank Technology: Enables continuous operation by allowing for non-stop gunning or the use of two different types of material.

- Water Dosing System: A proprietary system unique to EAF VARG, it provides precise moisture control, enhancing the durability and densification of the applied refractory material.

- Improved Controller: A significantly improved controller for the industrialisation phase is undergoing rigorous testing, offering features like a flip function to prevent lance distortion, offline reachability testing, and continuous movement to prevent over-gunning. Commissioning can be based on a CAD file of the furnace for improved initial installation.

- Customisation: Each EAF VARG unit is tailor-made and customised to individual furnace geometries, ensuring optimal performance and target-oriented gunning.

EAF VARG provides a fully controlled application process with servo-controlled, highly precise movements, ensuring accurate product placement and defined, even thickness on the furnace wall. It leverages the Vesuvius Gun Map Manager software to facilitate the entire repair sequence, from scanning to confirmation of the repair.