Carbon Bonded Working Linings

Benefits of Vesuvius solutions

- Improved corrosion resistance

- Cleaner steel

- Reduced CO2 emissions

- Energy savings

- Potential to increase ladle capacity

Engineered materials

Supermag* range of standard and low carbon steel ladle products

Low-carbon material technology

- Low carbon: reduces the potential for carbon pick-up in the steel melt

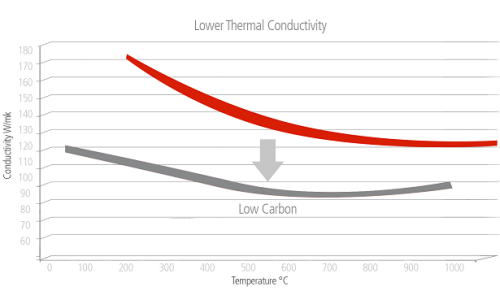

- Low conductivity: offers lower heat transfer and energy losses from the ladle

- Excellent slag resistance: comparable to high carbon containing products

- Optimized structural flexibility: to maintain good resistance to thermo-mechanical cracking and spalling

| Low carbon material technology | |||

|---|---|---|---|

| Ladle area | Typical material | Typical steel ladle carbon levels | Vesuvius target carbon level |

| Slag line | Magnesia-carbon (MgO-C) | 10-12% C | 5-7% C |

| Sidewall | Magnesia, antioxidants & graphite (AMG) Megnesia alumina carbon (MAC) Magnesia carbon (MgO-C) brick |

5-8% C | 2-4% C |

| Bottom | AMG or MgO-C brick | 5-8% Carbon |

2-4% Carbon |

Cast Ladle Lining Solutions

Benefits of Vesuvius solutions

- Contain steel and slag safely

- Maximise capacity - utilising the thinnest lining possible

- No negative effect on steel quality

- Long, balanced and predictable life

- Low heat loss

- Low thermal capacity

- Keep shell cool

- Optimised steel yield

- Low carbon footprint

Engineered materials

Synthetic Spinel & Spinel-Forming Castables

Self-Flow“

Installation expertise

- Design Services

- Experienced installation personnel - either Vesuvius’ installation teams or certified partners – trained to optimally install all Vesuvius Monolithic Refractory solutions, using approved installation equipment.

Installation equipment

Specialized installation equipment; designed to obtain the optimal installation efficiency and lining performance from Vesuvius Monolithic Refractory materials

Ladle Lining Maintenance

Engineered lining maintenance utilizing laser measurement technology with robotic gunning repair.