產品概覽

由於鑄件外型導致無法由鑄件週邊入水的關係,鑄造人員經常面對如何安排合適鑄件位置與補充的問題。這可能是由於造模設備或模板空間有限所致。

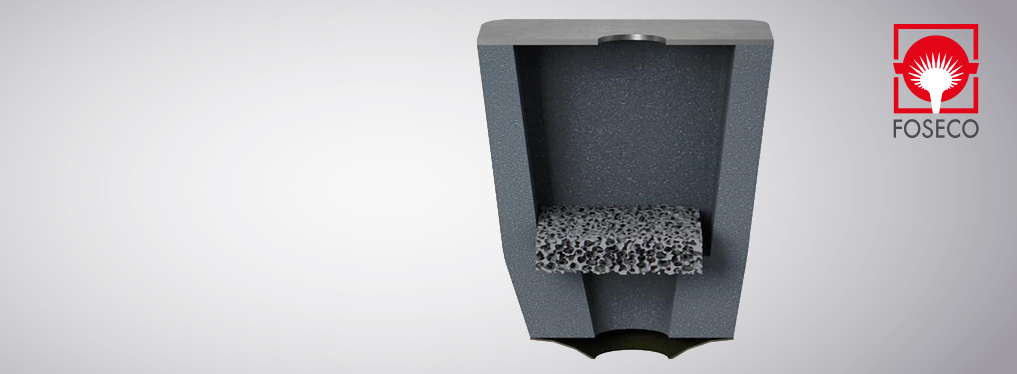

藉由 Foseco 開發的新 KALPUR,鑄造人員可以首次將直接澆鑄技術應用於濕砂模自動造模線上。這意味著,現在可以在無法進入的上模中實現直接澆注的特定優勢,例如提高得料率和好的方向性凝固。

觀賞左方短片以了解更多

主要益處

- + 降低後處理成本

- + 減少非金屬類夾渣

- + 減少因亂流引起的瑕疵

- + 改善方向性凝固

- + 鑄件表面佳與優化得料率

Discover who we are.

Vesuvius is a global leader in metal flow engineering, providing a full range of engineering services and solutions to its customers worldwide, principally serving the steel and foundry industries.

The main principle of Vesuvius' Investor Relations is to deliver timely, accurate and relevant information to Vesuvius' stakeholders.

Vesuvius has identified the practices within its operations that can directly or indirectly contribute to the United Nations Sustainability Goals (SDGs). We will focus our efforts on the following six SDGs where we believe we can make the most meaningful contribution.

The dedication and professionalism of our people is the most significant contributor to Vesuvius’ success.

Here you can read all our latest press releases, updates and event information.

產品概覽

由於鑄件外型導致無法由鑄件週邊入水的關係,鑄造人員經常面對如何安排合適鑄件位置與補充的問題。這可能是由於造模設備或模板空間有限所致。

藉由 Foseco 開發的新 KALPUR,鑄造人員可以首次將直接澆鑄技術應用於濕砂模自動造模線上。這意味著,現在可以在無法進入的上模中實現直接澆注的特定優勢,例如提高得料率和好的方向性凝固。

觀賞左方短片以了解更多