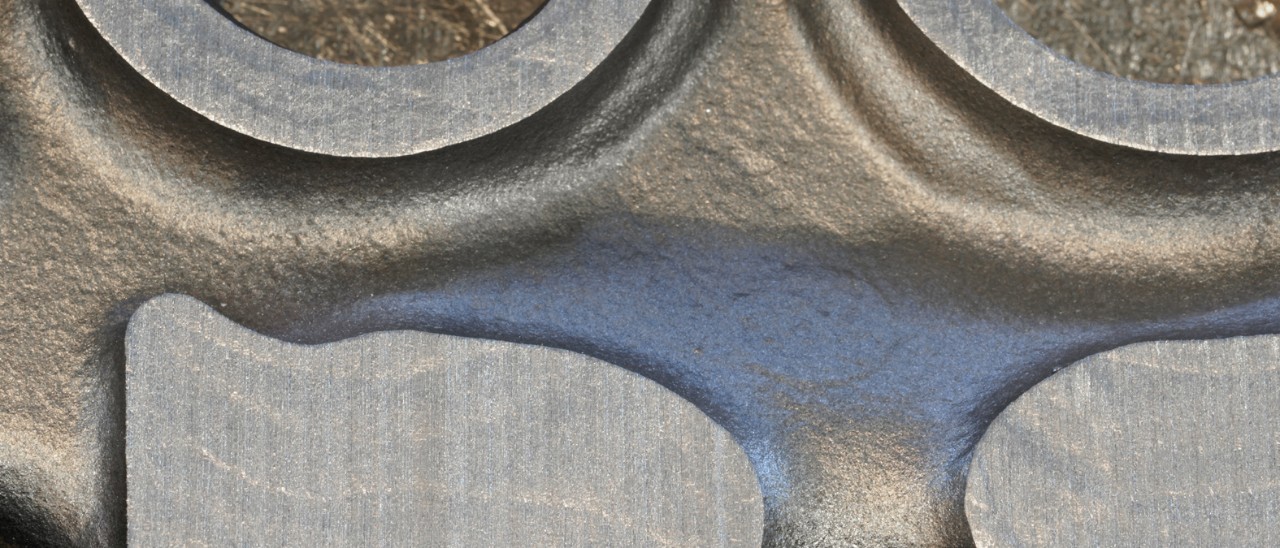

SEMCO IC – A New Foundry Coating Improving Inner Cleanliness for the Latest Engine Technology

Today the influence of a coating applied at a thickness of about 3 human hairs goes way beyond the actual cast component; it can beneficially improve the surface roughness resulting in an improvement of the performance of the engine and extend the service interval frequency of modern combustion engines.

The choice of the right refractory coating during casting production can influence engine performance to a degree that longer service intervals can be applied as well as the replacement of cooling and lubrication fluids reduced. These improvements can contribute directly to environmental requirements laid down by Euro 6 and future Euro 7 regulations.

The new range of “Inner Cleanliness” coatings from Foseco will help automotive foundries to deliver the increasing quality demands specified for the next generations of emission-reduced and performance-enhanced internal combustion engines.

Major Benefits:

- Reduction of remaining dirt in inaccessible parts of the engine (head and block)

- Reduction of rework and cleaning costs

- Improvement of engine performance

- Extension of service intervals

- CO2 emission reduction

- Reduced impurities in the cooling circulation system

Click here to read more