What is ANTERIS 360?

The manufacturing industry is an ever-changing, competitive field. It requires innovation, accuracy, and most importantly, safety. Meet ANTERIS 360 - the most advanced laser contouring system on the market for metallurgical applications.

ANTERIS 360 laser contouring system combines high-speed laser scanning technology with a robust mechanical platform and easy-to-use HYPERION 3D output software. It is designed to be inserted in the vessel and perform a single, 360 degrees scan, which will capture the full vessel. It can be used in ladle applications to “see” past the skull aggregate which can, in some circumstances, obstruct the view of the slag line as seen by other traditional scanners. Integration usually requires a simple single axis manipulator, which lowers both long and short terms costs. The results are superior scanning operations performance (accuracy, insert-ability and cycle time) for all vessel types.

Main benefits

Industrial furnaces present safety risks and require maintenance to optimize their availability and life. Thanks to ANTERIS 360, you can detect cracks, avoid premature shutdown, and extend refractory lifetime.

- Safety

- Ultimate scanning efficiency (single 360 degree scan)

- Can be inserted (almost) in any vessel

- Optimizes vessel availability

- Extension of refractory lifetime

- Highly customizable solution for most applications

- Fastest, most accurate scanner on the market

Fast, Accurate, Reliable Refractory Profiling

ANTERIS 360 is compatible with almost all types of vessels in a steel plant:

- BOF

- AOD

- EAF

- Iron Ladle

- Steel Ladle

- Torpedo Ladle

It can be integrated with a furnace by a simple single-axis manipulator, which lowers long and short-term costs.

It combines high-speed, laser scanning technology with a robust mechanical platform and easy-to-use Hyperion* 3-D output software on an insertable platform. Using Vesuvius new 300 kHz Anteris 360 laser contouring system, millions of contour points comprise each measurement, providing incredibly detailed surface and feature resolution in a few seconds.

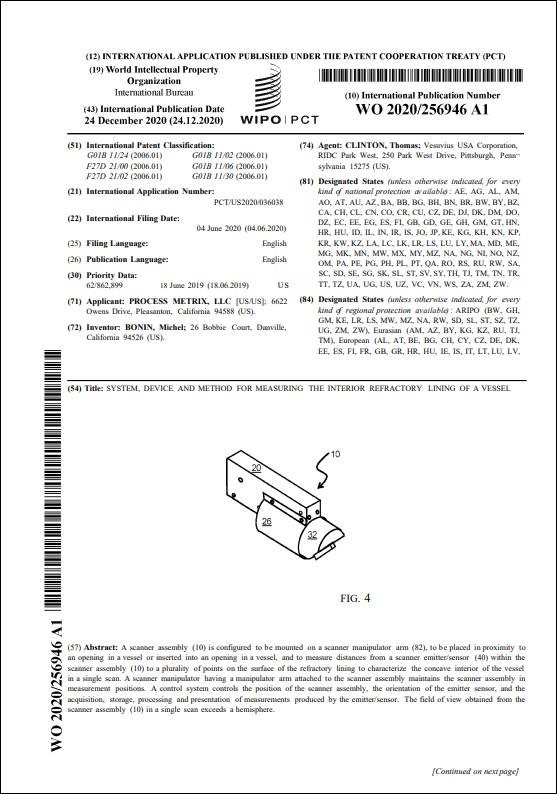

Patent

ANTERIS 360 is underpinned by patented technology for measuring the interior refractory lining of industrial vessels. The patented system and method enable precise, non-contact distance measurements from inside the vessel using a compact, scanner-based assembly mounted on or near the vessel. By characterizing the condition and geometry of the refractory lining during operation or inspection, the technology supports accurate assessment, improved maintenance planning, and enhanced operational safety.

Protected under international patent publication WO 2020/256946 A1, this innovation reflects a rigorously engineered approach to refractory measurement in demanding metallurgical environments.