Benefits of Vesuvius solutions

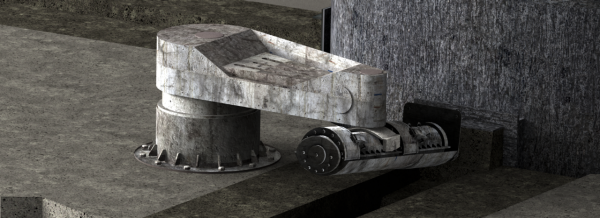

- Provide safe and reliable plugging and opening of the Taphole.

- Reduce Hearth and Taphole area wear by maintaining a consistent Taphole length.

- Specialised grouting products reduce crack propagation.

- Maintain uniform cast times by providing consistent iron and slag erosion and corrosion resistance.

- Minimise Taphole spraying during reduced cast-to-cast intervals.

- User-friendly nozzle cleaning.

- Environmentally responsible by reducing emissions.

Engineered materials

Vesuvius provides a diverse product offering tailored to meet the specific operational requirement of any Blast Furnace. Vesuvius presents a product offering comprised of various compositions and binder systems depending upon the specific customer operating parameters. Resulting in a wide range of Taphole Clays matching all processes and all local environmental legislation:

- High Alumina, SiC and FeSi3N4 Taphole Clay for very high output Blast Furnaces (>12,000 ton/day).

- Sur-Tap*

- Kingtap*

- Alumina-based Taphole Clay for low pressure Blast Furnaces.

- Surstop*

- Specialised grouting products to fill and prevent further crack propagation through the lining structure surrounding the Taphole

Expertise

Vesuvius experts globally provide diagnostic services to investigate and solve challenges in this critical area.

Vesuvius offers a global manufacturing capability to expertly produce high quality Taphole Clay in six plants throughout the world:

- UK

- USA

- Poland

- Australia

- South Africa

- India

Vesuvius offers Research & Development expertise. Vesuvius maintains two main R&D centres:

- UK

- USA

Supported locally at 3 locations:

- Australia

- South Africa

- India

These R&D centres maintain technical assistance at each site where we customise products based on the specific customer operation, equipment or process requirements.