Product Overview

Foundrymen are often faced with the problem of finding a suitable casting and feeding technique for castings that are difficult or impossible to ingate from their perimeter. This may be due to the nature of the component or limited space on the pattern plate.

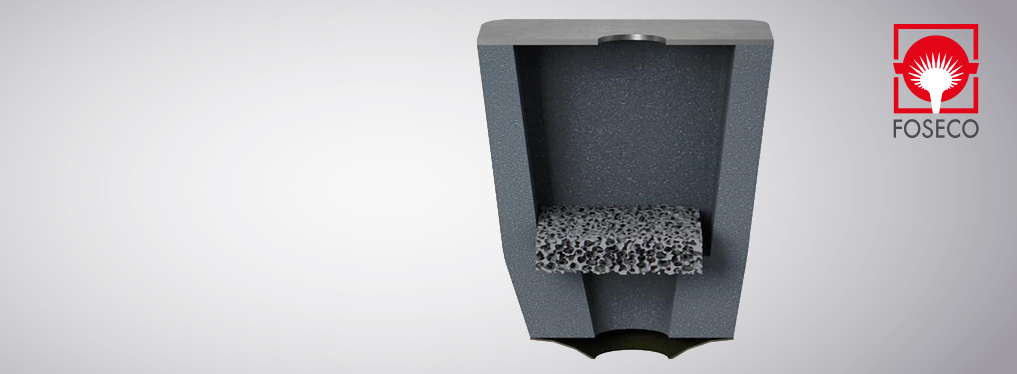

With Foseco’s new KALPUR development, foundrymen can for the first time apply the direct pouring technique to automatic green sand moulding lines. This means that the specific advantages of direct pouring, such as improved yield and directional solidifcation can now be realised on moulding lines where access to the cope is not possible.

Watch the video on the left to learn more.

Key Benefits

- + Reduced fettling costs

- + Reduced non-metallic inclusions

- + Lower turbulence related defects

- + Improved directional solidification

- + Good surface finish optimised yield