Controlling the flow of steel from the tundish to the mould is very important for Conventional Slab Casters. It strongly contributes to the ability to produce the optimum steel quality with the maximum caster safety.

Achieving the highest steel quality and minimizing production downgrades or stops requires:

- a precise and reliable control of the molten steel that guarantees a stable, level meniscus

- an optimized introduction and distribution of steel in the mould

- an appropriate formulation and consistent distribution of mould flux

Vesuvius brings its skills and experience to develop and service cutting edge solutions that maximize production quality and throughput with the highest level of safety. The integration of Avemis, Sert Metal and Metallurgica enlarged the Vesuvius portfolio and experience in this field.

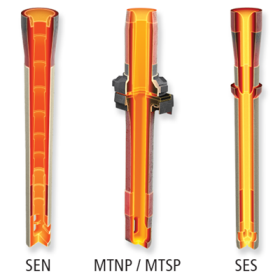

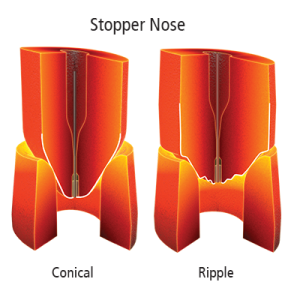

Shroud

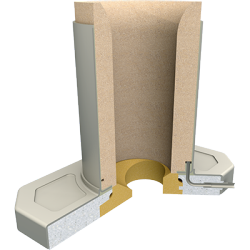

VISOTM Shroud: Tundish to mould shrouding

Level Control

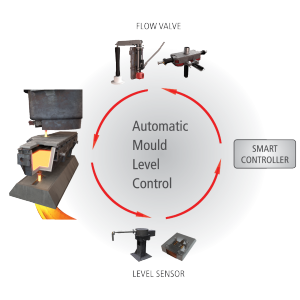

AMLC: Automatic Mould Level Control and associated flow valve refractories

The major components involved into the Vesuvius AMLC loop are:

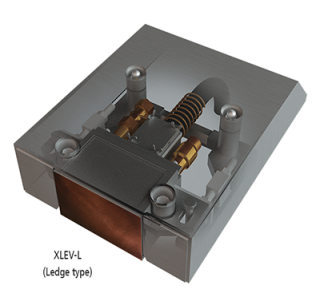

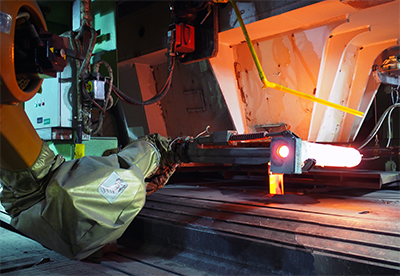

XLEV™ Eddy Current mould Level Sensor (Avemis technology)

Primary objectives:

- Provide accurate meniscus level measurement and short response time

Main features:

- Measurement not influenced by mould flux

- Wide choice of sensor heads, ledge or suspended

- Fully digital signal processing for a robust measurement

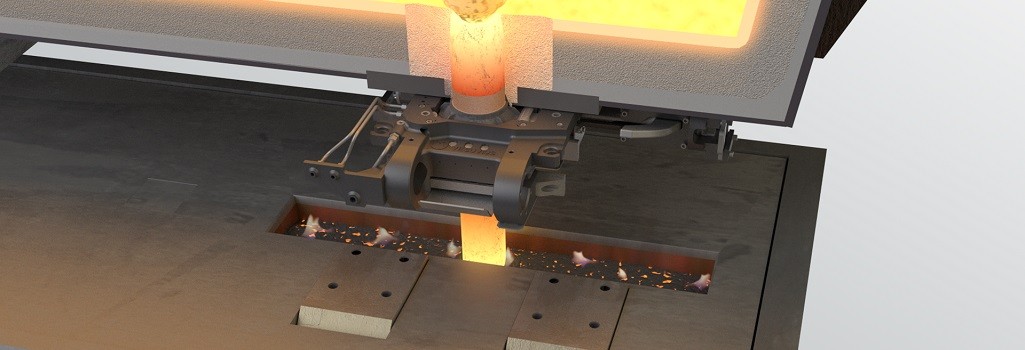

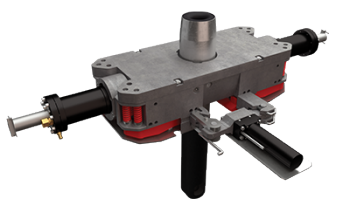

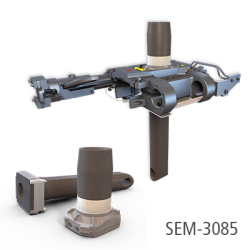

Tundish Slide Gate

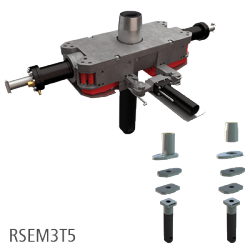

RSEM3T5™ Tundish Slide Gate with Tube Changer

Primary objectives:

- Accurate and fast flow control adjustment from tundish to mould

- Capable to change shroud tube for longer tundish sequence

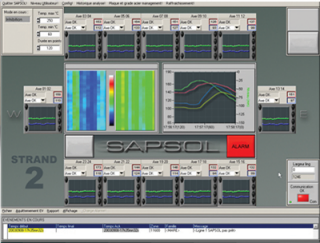

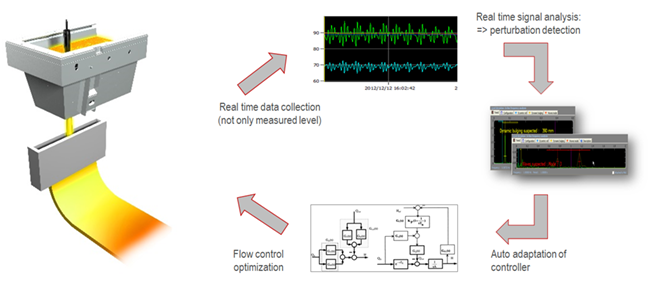

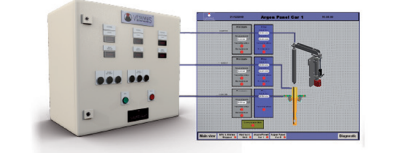

AMLC - Smart Mould Level Controller

Primary objectives:

- Drive the flow valve to minimize meniscus deviation

- Self-adapt to perturbations in process

Main features:

- Decide in real time the best control strategy along casting sequence

- Minimize meniscus fluctuation when strong perturbations occur

- Auto-adapts to bulging, waves or other periodical fluctuation (option)

- Optional functions: strand Autostart, Automatic Tube Change

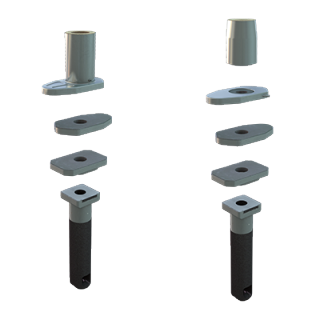

Tube Changer

Shroud Exchange Mechanism

Gas Inerting

Inert Gas Control for steel protection

Primary objectives:

- Management of inert gas application to reduce risk of air ingression

Main Features:

- Multi-channel control panel, using mass flowmeters

- Double line per loop with back pressure measurement (option)

- 3 operating modes (option): Automatic Flow Control, Automatic Pressure Control, Manual

Flux Powder

Flux Powders and Distribution Mechanisms

Primary objectives:

- Create lubrication layer between steel shell and mould faces,

- Protect steel top surface from re-oxidation and heat loss,

- Control heat transfer between strand & mould,

- Capture inclusions floating to top surface

- Distribute the flux regularly over the steel surface

BO Prevention

Breakout Prevention System