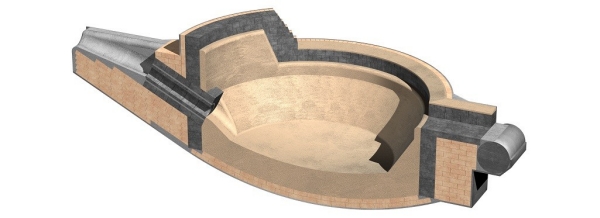

Taphole design launder tapping furnaces

For conventional syphon or submerged entry tapholes, Vesuvius can supply either assemblies with repair sleeves for use with furnace gate tap hole systems or large preassembled shapes.

In addition, Vesuvius can supply single-piece, iso pressed tapholes. These can offer benefits over traditional taphole systems, where joint penetration and subsequent loss of individual taphole sleeves is a problem.

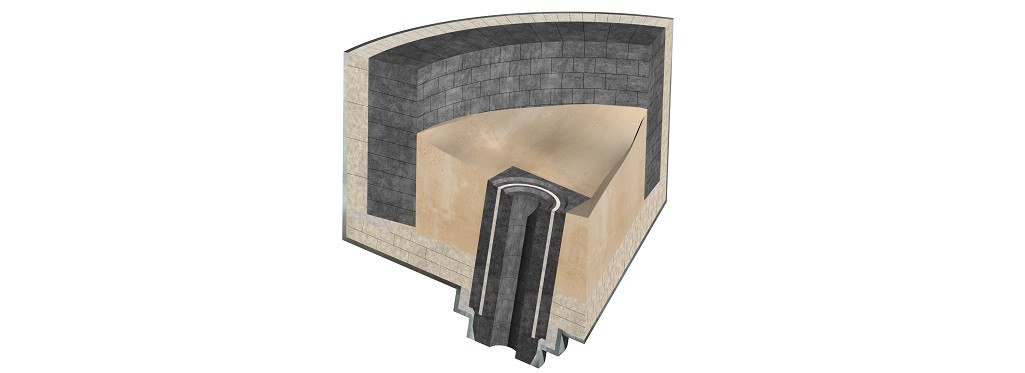

Bottom tapping furnaces

Vesuvius can provide world standard refractories no matter which type of bottom tapping system is utilised.

- Tap time reduced

- Less heat loss

- Minimises slag carryover

- Improves steel cleanliness

- Minimises taphole repair time

Benefits of Vesuvius solutions

- Optimised campaign life

- Optimised vessel performance and reduced vessel repair cost

- Increase vessel availability and productivity

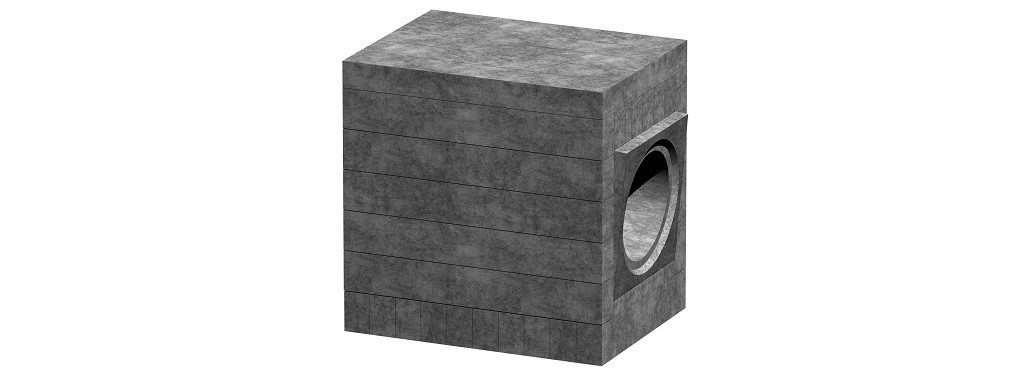

Engineered Materials

- High quality Fused Magnesia Supermag* solutions enriched with up to 15% Carbon

- Pressed into individual pieces for either pre-assembly on assembly on site

- Isostatically pressed into a single piece for enhanced performance