Foseco offers the foundryman a complete range of silicon carbide and clay graphite crucibles, retorts and other specialized shapes for use in fuel fired, induction and electric resistance furnaces. Furthermore a broad range of monolithic and precast products are available for aluminium, zinc and copper melting and holding furnaces and Foseco personnel are on hand to offer advice on product selection, maintenance and design.

Crucibles

ENERTEK

ENERTEK crucibles are a new family of energy efficient crucibles that have been formulated and manufactured to offer the most thermally efficient crucible for aluminum melting and holding in in electric resistance furnaces.

DURATEK

DURATEK crucibles offer excellent oxidation resistance and thereby give extended service life compared to standard crucibles in electric resistance furnaces for aluminum melting and holding applications.

KING-CARB

KING-CARB crucibles are designed for most flame-fired, electric resistance and low frequency induction. Applications with high thermal conductivity, high density and low porosity properties.

TERCOD

TERCOD crucibles are available in a full range of crucible sizes. Excellent in flame-fired applications (aluminum, brass/bronze/copper), but are also used in low-frequency induction applications. TERCOD is highly resistant to thermal shock, has excellent mechanical strength, and a low coefficient of thermal expansion.

DIAMANT Special

Premium quality, isostatically pressed crucibles for low temperature applications with good thermal conductivity and chemical attack resistance. Ideally suited for the melting and holding of aluminium as well as other low temperature applications.

DIAMANT Universal

Premium quality, isostatically pressed crucibles with good thermal conductivity. Suitable for a wide range of applications including the melting and holding of copper alloys, the melting of aluminum in flame fired furnaces, precious metals and zinc distillation.

DIAMANT Top

Isostatically pressed crucibles with very high electric resistivity. Specially designed for use in high frequency and/or high power induction furnaces.

DIAMANT Optimal

Isostatically pressed, carbon bonded crucibles with very low electric resistivity. Ideally suited for use in low- and medium frequency induction furnaces.

Precast Shapes

INSURAL for aluminum and zinc

INSURAL ATL insulating ladle linings are suitable for aluminum and zinc foundries. The preformed ladle linings are used to transport molten aluminum and zinc alloys and possess excellent non-wetting characteristics and superior temperature retention.

INSURAL 700 and INSURAL 800 pastes are highly insulating mastics which are used as adhesives but can also be used for repairs, make seals or for similar tasks. Ideally suited to aluminum and zinc, they can also be applied to other non ferrous alloys provided the temperature lies below 1000 ºC.

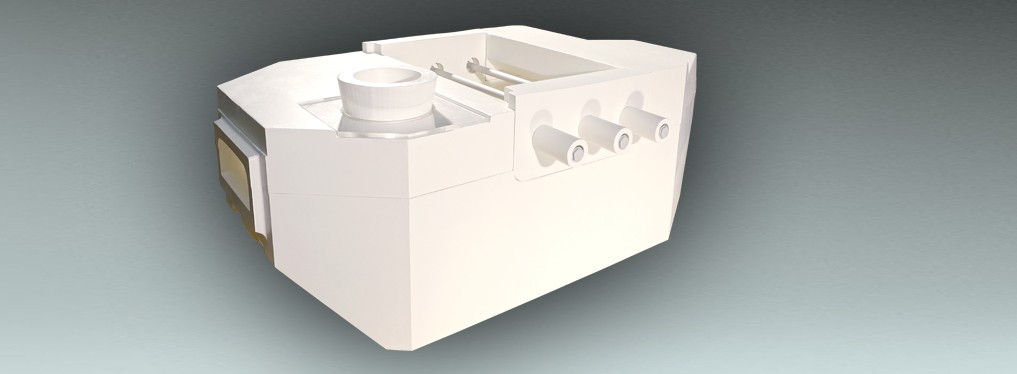

INSURAL precast shape components are also available for use in low-pressure diecasting furnaces, dosing furnaces and other aluminum contact applications. Our advanced precast furnace assemblies combine INSURAL and ZYAROCK components with suitable backing materials, and deliver lower energy consumption and excellent melt quality within a short period upon commissioning and throughout the life of the lining.

INSURAL lining systems can be installed on site at the customer facility or off-site at a Foseco-approved furnace installation company. Furnace downtime during re-lining is minimal with installation of the INSURAL lining system typically completed within 3 days and with no refractory sintering or dry out process necessary.

ZYAROCK and ZYACAST fused silica for aluminum

High purity fused silica preformed shapes such as pouring basins, shot sleeves, launders low-pressure diecasting tubes and ladles.

KALTEK preformed one-piece insulating linings for copper

KALTEK shanks are preformed insulating linings designed for the transfer and pouring of molten copper based alloys. They are available for ladles of up to 1000 kg capacity.

Castable Linings for Aluminium and Copper

TRIAD is a range of user friendly, no-cement castables with excellent non-wetting characteristics, erosion resistance and longevity. TRIAD 70 is mulcoa based with low density and high resistance to aluminium penetration and is therefore ideally suited for channel holding furnaces, tower melters and low pressure diecasting furnaces.

ALUGARD is a range of materials specifically developed and designed to resist erosion and impact damage whilst retaining excellent non-wetting properties in aluminium alloys.

ALUGARD products also minimise the potential for corundum formation and growth in aluminium and associated alloys.

QUICK FIX 85AL is ideal for patch repairing furnaces and thin veneer repairs.

ZYACAST LPS fused silica castable is a high-purity fused silica castable for the transport of aluminium alloys.

KALTEK ISO 18S is a castable powder with an inorganic bonding system generated by an exothermic reaction suitable for copper base foundries.

ONYX is a range of alumina based phosphate bonded plastics containing silicon carbide.

CRITERION is a range of high strength, low cement, abrasion resistant castables for the hearth and shaft.

Coreless Induction Furnace

Refractory systems for the reline and maintenance of coreless furnaces melting or holding aluminium alloys

- KELLUNDITE 352 is a high alumina based dry lining providing a clean operating furnace with minimum dross build up

- KELLUNDITE 354 is a high alumina based “seamless” dry capping with enhanced erosion resistance

- BLU-RAM HS, BLU-RAM HSW, BLU-RAM TR and BLU RAM PC are granular phosphate bonded plastics for furnace capping and spouts

- TRIAD 45 and TRIAD 70 precast spouts

- KELLUNDITE G alumina based, cement bonded grout for coating the induction coil

Refractory systems for the reline and maintenance of coreless furnaces melting or holding copper base alloys

- KELLUNDITE 410 is a silicon carbide containing, alumina based dry linings for copper melting furnaces

- 85 RAM HS, 85 RAM TR and 85 RAM PC are alumina based phosphate bonded plastics for patching repairs and maintenance work.

- KELLUNDITE G alumina based, cement bonded grout for coating the induction coil